Large vertical mill is widely used in the modern cement industry and the maintenance of their supporting components is related to the normal production of vertical mills. The large reducer supporting the vertical mill should be included in this column. Once an accident occurs, the site maintenance is difficult, the technical content is high, and the maintenance cycle is long, which has a great impact on the normal production and operation of enterprises. Many cement enterprises' response measures are: to spend high costs to purchase spare machines, in case of a rainy day; Or the use of winter peak stop production opportunities, the machine back to the factory maintenance, is bound to spend high back and forth transportation costs. This shows that the on-site inspection and maintenance method of the large reducer is very important.

Professional inspection: Device inspection is the most important method to discover potential faults.

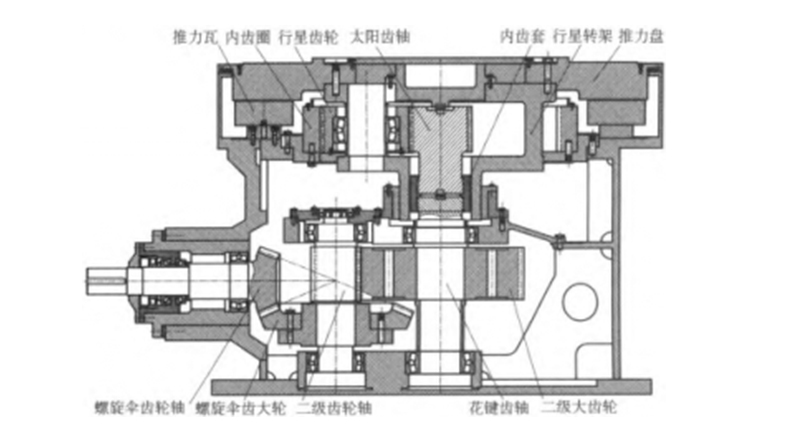

Common faults: high speed shaft bearing damage, high speed shaft bevel gear tooth broken, high speed shaft two bearings between the interval sleeve loose, parallel axis external tooth spline shaft and internal tooth spline sleeve surface wear, equipment vibration

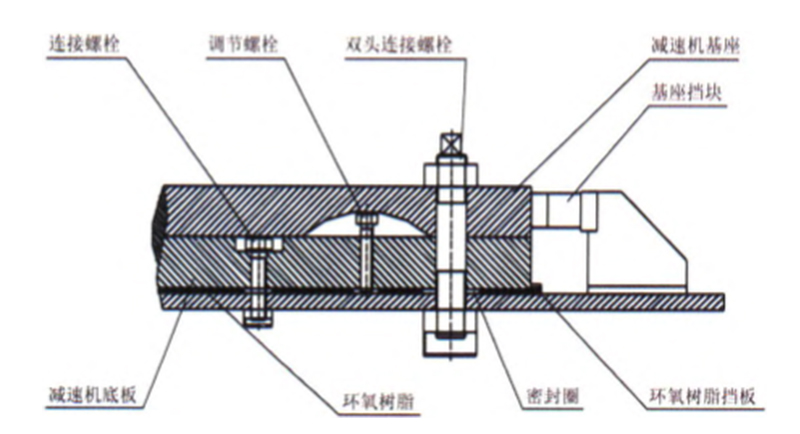

Fault maintenance: invite the professional maintenance team to perform on-site maintenance on the factory's reducer and treat any shaking foundation issues.

Review on incineration compatibility of hazardous waste

The compatibility of hazardous waste for feeding is a crucial step in the incineration disposal process, ensuring economical and dependable combustion. It supports stable operation, equipment protection, increased capacity, meeting discharge standards, and reducing costs.

1. Ensure that the calorific value of materials entering the rotary kiln is stable within a certain range to ensure the economy and reliability of system operation.

2. Control the proportion of halide and organic matter to reduce the corrosion of waste heat boiler and flue gas treatment equipment caused by acid pollutants in flue gas produced by combustion.

3. Control the content of halides and heavy metals to ensure the treatment effect of incineration smoke and normal exhaust emissions.

Control the content of chlorine-containing organic waste in the kiln, and reduce the generation of dioxins in the incineration process from the source.

5. Control alkali metal and other low melting point content, control system coking and structure blockage, reduce the impact on refractory materials.

6. Make full use of a variety of feeding channels and stable burning conditions to avoid large instantaneous fluctuations when entering the kiln.

7. Control the moisture stability of materials to ensure the normal drying stage of waste and improve waste disposal efficiency.

The composition and structure of polymer waste are quite complex. In the process of combustion, they can be completely decomposed into low-molecule combustible gas through continuous multistage thermal decomposition reaction, and finally converted into combustion reaction, and release combustion heat.

When burning plastics, rubber, paint, and asphalt, the resulting smoke can spread up to 30-40 meters in the air due to incomplete thermal decomposition, uneven combustion oxygen supply, and incomplete combustion. This can lead to billowing black smoke, which is caused by these factors.

Technology | Fourth-generation tail roller broken upgrade of grate cooler

1. Analysis of existing problems

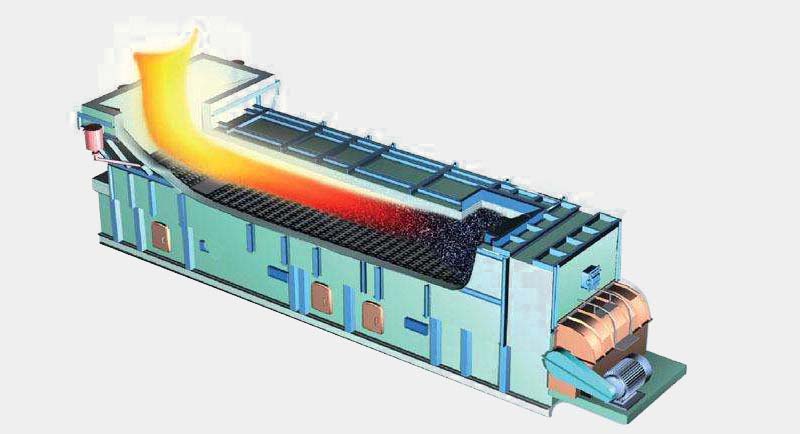

The firing system of the production line is equipped with a ф4.8m×72m rotary kiln, a five-stage double-series preheater, and a grate cooler for the fourth generation of stepping grate coolers. The main problems before the transformation are as follows:

(1) The second and third air temperature of grate cooler is not high, and the second air temperature is about 1050~1100℃, and it is unstable.

(2) The grate cooler covers an area of only 138.3m². The outlet clinker temperature of the grate cooler is often higher than 120℃, and red material sometimes appears.

(3) Power generation per unit of clinker waste heat is low.

2. Solutions

(1) Automatic air volume control valve, saves wind and electricity, helps to ensure the thermal stability of the system;

(2) With the snowman elimination device, so that the grate bed layer is more stable;

(3) High heat recovery efficiency, generally guaranteed above 75%, to avoid the phenomenon of high temperature of outlet clinker;

(4) The use of a decentralized independent single-row hydraulic drive, high reliability of operation, greatly reduces the risk of kiln shutdown due to grate cooler failure;

(5) The use of cross rod conveying clinker, its high conveying efficiency, less wearing parts, low maintenance;

(6) Modular grate bed, grate plate fixed, only cooling effect, high reliability;

(7) The use of special sealing structure, no leakage, no leakage conveying device, low maintenance;

(8) Strong crushing capacity of the roller, the large diameter of the crushing roller, and equipped with a "lower roller" (increased crushing Angle, strong crushing capacity of large materials), frequency conversion speed regulation.

The plan includes demolishing the grate cooler and cooling fan, connecting the shell with waste heat power generation and waste gas outlet, replacing the crossbar grate cooler, and connecting a new grate cooler outlet discharge valve directly to the inclined zipper machine.

3. Program implementation

The transformation will be carried out during the overhaul period after the Spring Festival of 2021, lasting a total of 40 days, to ensure the re-ignition and feeding of the production line to the maximum extent. So far, production has been stable.

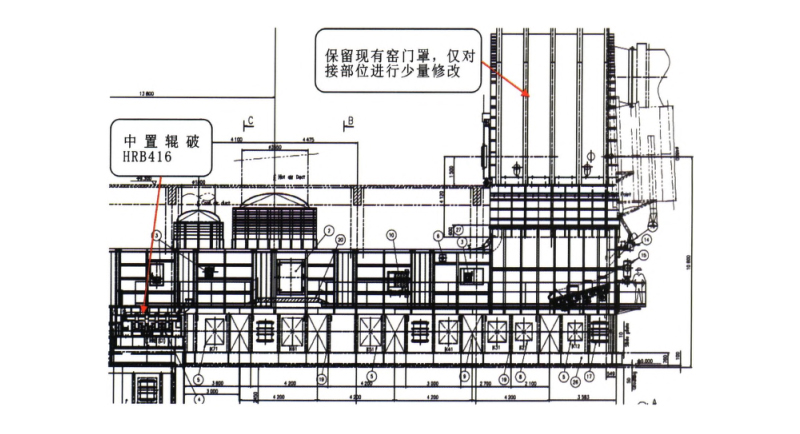

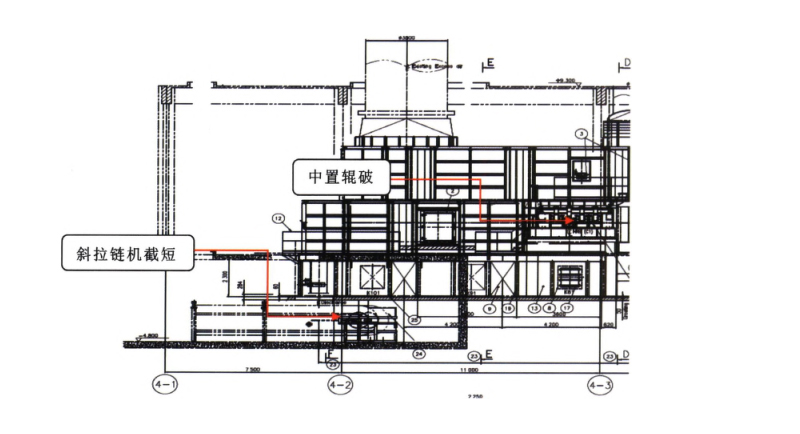

The modification of grate cooler in front of middle roller break is shown in the diagram. For the grate bed and intermediate crusher after the new grate cooler roller is broken, the foundation shall be excavated and made again. The grate bed foundation of the section after roller breaking is about 2.3m below the ground. The base elevation of the zipper remains the same in order to minimize civil excavation. The transformation of the new grate cooler after the middle roller is broken is shown in the figure.

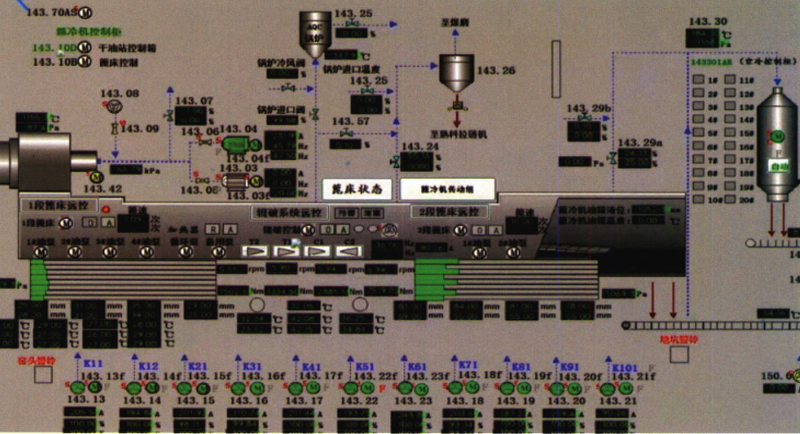

4. Technical transformation effect

After modification, the equipment runs stably, and the secondary air temperature runs stably above 1150℃. See the equipment configuration and effect comparison before and after the cooling machine transformation.

The grate cooler is crucial for clinker cooling and conveying in sintering equipment. Its performance directly affects the operation rate, coal consumption, and power consumption of the firing system. Many cement companies are optimizing and transforming their grate coolers to improve efficiency. Technical modifications have shown that the central roller breaker ensures the outlet clinker temperature is always lower than +65℃, regardless of kiln conditions and clinker gradation, allowing for more efficient use of waste heat for power generation.

Submit Request