The HP series of hydraulic cone crushers is ideal for mining, building materials, and metallurgy industries. It is capable of performing medium and fine crushing operations on materials with a medium to high level of hardness, such as iron ore, copper ore, granite, basalt, cobbles, marble, limestone, etc. Due to its exceptional performance, the HP series hydraulic cone crusher is widely used in highly automated crushing production lines.

Whatsapp:

+8613917653369Email:

[email protected]The principle of inter-granular lamination designs the crushing cavity of hydraulic crushers; it replaces the traditional single-particle crushing principle, achieving selective crushing of materials and uniform crushing particle size. The crushing chamber adopts high-performance, non-contact labyrinth seals, which improve the reliability of blocking dust and reduce iron pollution and equipment wear cycles. In addition, Combined with the machine body's unique thin oil lubrication system, the equipment's service life is significantly extended.

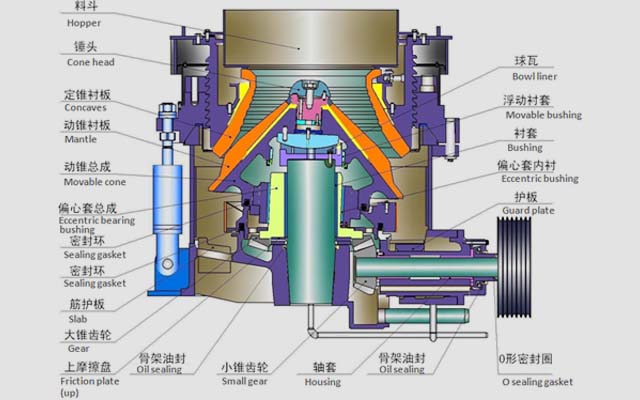

The whole working process of hydraulic cone crushers is that the motor drives the rotation of the transmission shaft by belt pulley and v-belts. In turn, it drives the eccentric sleeve around the main shaft using the spiral bevel gear, continuously compressing or squeezing the materials. The materials are crushed and ground from all directions, forming high compressive strength building aggregates. Finally, the small-sized materials fall through the narrow opening at the bottom of the crusher.

| Model | Cavities | Feed opening (mm) | Minimum discharging size (mm) | Capacity (t/h) | Motor Power (kw) | Items dimension (mm) |

| HP100 | C1(Extra Coarse) | 140 | 19 | 75-140 | 90 | 1705X1510X1583 |

| HP100 | C2(Coarse) | 100 | 13 | 60-110 | 90 | 1705X1510X1583 |

| HP100 | M(Medium) | 70 | 9 | 52-100 | 90 | 1705X1510X1583 |

| HP100 | F1(Fine) | 50 | 9 | 50-95 | 90 | 1705X1510X1583 |

| HP100 | F2(Extra Fine) | 20 | 6 | 45-90 | 90 | 1705X1510X1583 |

| HP160 | C2(Coarse) | 185 | 19 | 145-250 | 160 | 2135X1750X1927 |

| HP160 | M(Medium) | 125 | 16 | 135-235 | 160 | 2135X1750X1927 |

| HP160 | F1(Fine) | 95 | 13 | 115-220 | 160 | 2135X1750X1927 |

| HP160 | F2(Extra Fine) | 75 | 10 | 90-190 | 160 | 2135X1750X1927 |

| HP220 | C1(Extra Coarse) | 230 | 25 | 220-440 | 220/250 | 2725X2110X2871 |

| HP220 | C2(Coarse) | 210 | 19 | 190-380 | 220/250 | 2725X2110X2871 |

| HP220 | M(Medium) | 150 | 16 | 175-320 | 220/250 | 2725X2110X2871 |

| HP220 | F1(Fine) | 105 | 13 | 145-280 | 220/250 | 2725X2110X2871 |

| HP220 | F2(Extra Fine) | 80 | 10 | 110-240 | 220/250 | 2725X2110X2871 |

| HPHP220315 | C1(Extra Coarse) | 295 | 30 | 300-630 | 315 | 2775X2370X2295 |

| HPHP220315 | C2(Coarse) | 251 | 25 | 285-560 | 315 | 2775X2370X2295 |

| HPHP220315 | M(Medium) | 196 | 20 | 250-490 | 315 | 2775X2370X2295 |

| HPHP220315 | F1(Fine) | 110 | 13 | 180-345 | 315 | 2775X2370X2295 |

| HPHP220315 | F2(Extra Fine) | 90 | 10 | 135-320 | 315 | 2775X2370X2295 |

| HP400 | C1(Extra Coarse) | 330 | 38 | 425-790 | 400 | 2800X3480X4050 |

| HP400 | C2(Coarse) | 290 | 30 | 370-700 | 400 | 2800X3480X4050 |

| HP400 | M(Medium) | 210 | 22 | 330-605 | 400 | 2800X3480X4050 |

| HP400 | F1(Fine) | 135 | 16 | 270-535 | 400 | 2800X3480X4050 |

| HP400 | F2(Extra Fine) | 95 | 13 | 220-430 | 400 | 2800X3480X4050 |

| HP600 | C1(Extra Coarse) | 350 | 38 | 570-1200 | 630 | 3970X3345X4235 |

| HP600 | C2(Coarse) | 299 | 32 | 520-1050 | 630 | 3970X3345X4235 |

| HP600 | M(Medium) | 265 | 25 | 475-950 | 630 | 3970X3345X4235 |

| HP600 | F1(Fine) | 220 | 16 | 370-800 | 630 | 3970X3345X4235 |

| HP600 | F2(Extra Fine) | 150 | 13 | 310-60 | 630 | 3970X3345X4235 |

Submit Request