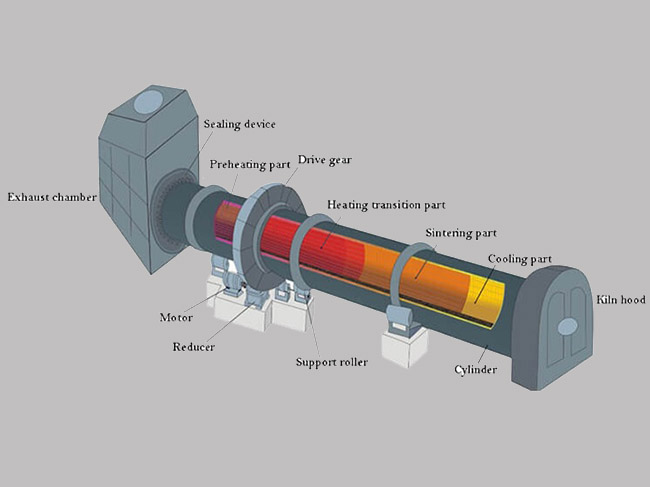

The ceramic rotary kiln is a rotating cylindrical equipment that integrates material preheating, drying, and firing. It is primarily used for the calcination of ceramic pellets. The ceramic pellet kiln features a high volumetric capacity, long service life, high operational efficiency, stable operation, high heat transfer efficiency, and low energy consumption. There is no doubt that ceramic pellet rotary kiln is an ideal equipment for calcining ceramic pellets.

Whatsapp:

+8613917653369Email:

[email protected]The Ceramic Rotary Kiln consists of a cylinder, feeding device, supporting device, supporting device with baffle wheel, kiln head, kiln tail sealing device, combustion device, dust removal device, motor, and other parts.

In a ceramic pellet rotary kiln, pulverized coal is burned to produce heat, which is then used to heat the material through gas conduction or radiation. The ceramic pellet rotary kiln rotates continuously at a designed inclination and speed, causing the raw materials to tumble and advance periodically, and convey from the feeding end to the discharge end. As the raw material passes through the rotary kiln, it undergoes calcination and transforms into a qualified clinker.

Ceramsite is a lightweight aggregate produced in a rotary kiln. These ceramic pellets have several excellent properties, including low density, high cylinder strength, high porosity, high softening coefficient, good frost resistance, and resistance to alkali-aggregate reactions. They are widely used in building materials, horticulture, food and beverage, refractory insulation materials, and chemical and petroleum fields.

| Specifications (m) | Output per hour(m3/h) | Annual output (10,000 m3/a) | Slope (%) | Cylinder speed(r/min) | Reducer | Cylinder speed(r/min) | Power(kW) | |

| Preheating kiln | φ1.25×18 | 2.95~3.94 | 1.8~2.4 | 4 | 1.0~5.0 | ZQ500 | YCT225-4A | 11 |

| Calcining kiln | φ1.6×14 | 2.95~3.94 | 1.8~2.4 | 4 | 1.0~5.0 | ZQ650 | YCT225-4B | 15 |

| Preheating kiln | φ1.55×20 | 4.36~5.81 | 2.67~3.5 | 4 | 1.0~5.0 | ZQ650 | YCT250-4A | 18.5 |

| Calcining kiln | φ1.9×16 | 4.36~5.81 | 2.67~3.5 | 4 | 1.0~5.0 | ZQ750 | YCT250-4B | 22 |

| Preheating kiln | φ1.8×22 | 5.9~7.87 | 13.61~4.8 | 4 | 1.0~5.0 | ZQ750 | YCT250-4B | 22 |

| Calcining kiln | φ2.2×18 | 5.9~7.87 | 13.61~4.8 | 4 | 1.0~5.0 | ZQ750 | YCT250-4B | 22 |

| Preheating kiln | φ2.0×24 | 7.42~9.88 | 4.54~6 | 4 | 1.0~5.0 | ZSY224 | YCT280-4B | 30 |

| Calcining kiln | φ2.5×20 | 7.42~9.88 | 4.54~6 | 4 | 1.0~5.0 | ZSY224 | YCT315-4A | 37 |

| Preheating kiln | φ3.0×20- φ2.5×12 | 9.5~17.51 | 8.04~10.7 | 4 | 1.0~5.0 | ZS1450 | YCT355-4B | 75 |

| Calcining kiln | φ3.0×22 | 9.5~17.51 | 8.04~10.7 | 4 | 1.0~5.0 | ZS1250 | YCT355-4A | 55 |

| Preheating kiln | φ3.2×20- φ2.8×14 | 13.9~16.2 | 10.0~11.5 | 4 | 1.0~5.0 | ZS1450 | YCT355-4A | 55 |

| Calcining kiln | φ3.0×22 | 13.9~16.2 | 10.0~11.5 | 4 | 1.0~5.0 | ZS1250 | YCT355-4A | 55 |

Submit Request