Input Size: particle size 15-40mm,

Capacity:15-50T/H

Material: Coal, limestone, calcite, quicklime, dolomite, talc, calcium carbonate, gypsum, kaolin and petroleum coke and etc.

Application field: Coal vertical mills are widely used in cement production, calcium carbonate crushing processing, coal powder preparation stations, gypsum powder processing, power plant desulfurization, phosphate rock grinding, metallurgical industry and other non-metallic ore powder making, etc.

Whatsapp:

+8613917653369Email:

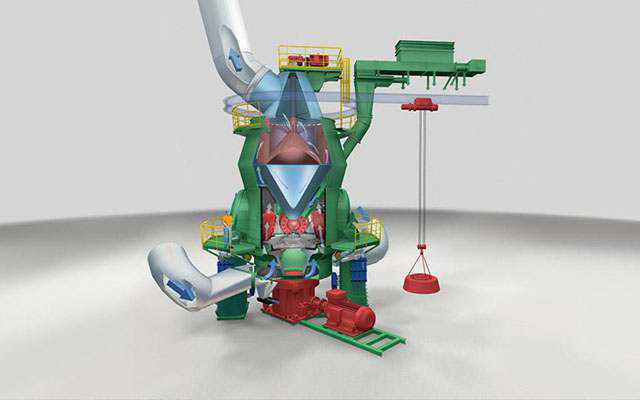

[email protected]The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company. It combines modern technology with our extensive experience in powder manufacturing. This coal pulverizer efficiently integrates coal grinding and drying, providing high-performance and energy-saving features. It is widely used in various industries such as cement, electric power, iron and steel, and metallurgy. Our grinding roller coal mill has a simple process, compact equipment, low dust emission, and efficient combustion of coal powder.

During operation, the main motor drives the grinding disc through a reducer. Hot air enters the vertical mill through the inlet, while the raw coal is fed evenly into the center of the grinding disc via the conveyor. The raw coal is crushed by the grinding roller as it moves evenly to the edge under the influence of centrifugal force. The crushed fine powder is carried away by the airflow from the air ring, and the qualified fine powder is collected and discharged as finished powder. Material that does not meet the fineness requirements is returned to the grinding disc for further grinding. The difficult-to-grind sundries mixed in are discharged out of the main machine through the scraper.

Application: used in pulverized coal injection, coal-fired boilers for power generation and heating boilers in the metallurgical industry, coal powder preparation in shaft kiln, coal chemical industry.

| Type specification | VRM800M | VRM1100M | VRM1250M | VRM1300M | VRM1500M | VRM1700M | VRM1900M | VRM2200M | |||||||

| Yield (t/h) | 3~5 | 5~8 | 9~13 | 13~17 | 18~22 | 22~30 | 30~40 | 40~50 | |||||||

| Maximum feed size (mm) | 15 | 20 | 25 | 25 | 30 | 30 | 35 | 40 | |||||||

| Raw coal moisture (%) | <10 | ||||||||||||||

| Fineness of pulverized coal (200 mesh pass %) | 80 | ||||||||||||||

| Coal moisture content (%) | ≤1 | ||||||||||||||

| Main motor Power (kW) | 55 | 110 | 132 | 180 | 250-250 | 315-280 | 400 | 500 | |||||||

Submit Request