The grid-type ball mill is an important piece of equipment used for crushing materials before further processing. It is widely utilized in the production of cement, silicate products, new construction materials, refractory materials, chemical fertilizers, ferrous and non-ferrous metal beneficiation, and glass ceramics. This equipment can be used for both dry and wet grinding of various ores and other grindable materials.

Whatsapp:

+8613917653369Email:

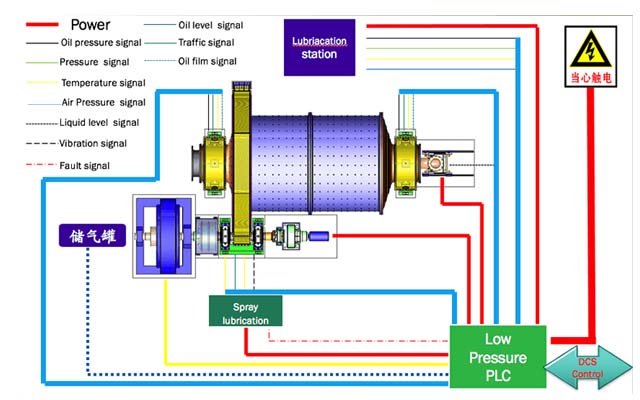

[email protected]The ball mill consists of six main parts: the cylinder, ore feeder, ore discharger, transmission device, bearing, and lubrication system. In a grid-type ball mill, the grid plate serves to isolate and enhance the impact of the medium ball, resulting in a stronger crushing effect on the material and achieving a very high grinding effect.

The grid-type ball mill is a horizontal cylindrical rotating device driven by outer gears and has two warehouses. The material is spirally and evenly entered into the first chamber of the mill through the feeding hollow shaft by the feeding device. The chamber has stepped lining boards or corrugated lining boards, and steel balls of different specifications are installed inside.

The rotation of the cylinder produces centrifugal force to bring the steel balls to a certain height. After falling down, it will hit and grind the material. Materials get coarse-grind in the first warehouse, then into the second warehouse through the single compartment. The second warehouse has a flat liner filled with balls, then grind the material again. The powder is discharged through the unloading grate plate to complete the grinding.

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Effective Volume (m³) | Max.Ball Loading (t) | Speed (r/min) | Capacity (t/h) | Discharging size(mm) | Main Motor (KW) | Weight (t) |

| MQG-1557 | 1500 | 5700 | 8.5 | 12 | 28 | 11-3.5 | 0.6 ~ 0.074 | 130 | 24.7 |

| MQG-1564 | 1500 | 6400 | 9.6 | 13 | 28 | 12.5-3.9 | 0.6 ~ 0.074 | 155 | 27 |

| MQG-1864 | 1830 | 6400 | 15 | 20 | 23.8 | 19.5-6 | 0.6 ~ 0.074 | 210 | 42 |

| MQG-1870 | 1830 | 7000 | 16 | 22 | 23.8 | 21 ~ 6.5 | 0.6 ~ 0.074 | 245 | 43.5 |

| MQG-1880 | 1830 | 8000 | 18.8 | 26 | 23.8 | 24-7.5 | 0.6 ~ 0.074 | 280 | 46 |

| MQG-2170 | 2100 | 7000 | 22 | 30 | 24.1 | 28 ~ 8 | 0.6 ~ 0.074 | 320 | 58 |

| MQG-2175 | 2100 | 7500 | 23.5 | 33 | 24.1 | 30-8.5 | 0.6 ~ 0.074 | 355 | 59.5 |

| MQG-2265 | 2200 | 6500 | 22 | 35 | 21.7 | 32-9.2 | 0.6 ~ 0.074 | 380 | 61 |

| MQG-2270 | 2200 | 7000 | 23.8 | 35 | 21.7 | 34.5-9.9 | 0.6 〜0.074 | 380 | 62.5 |

| MQG-2275 | 2200 | 7500 | 25.5 | 35 | 21.7 | 37.5-10.8 | 0.6 ~ 0.074 | 380 | 64 |

| MQG-2470 | 2400 | 7000 | 28 | 39 | 21.7 | 41-18.8 | 0.6 ~ 0.074 | 630 | 81 |

| MQG-2480 | 2400 | 8000 | 32 | 45 | 21.5 | 47-21.5 | 0.6 〜0.074 | 570 | 86 |

| MQG-2750 | 2700 | 5000 | 25.8 | 36 | 20.7 | 42-18.5 | 0.6 ~ 0.074 | 400 | 112 |

| MQG-2760 | 2700 | 6000 | 31 | 43 | 20.6 | 49-21.5 | 0.6 〜0.074 | 570 | 121 |

Submit Request