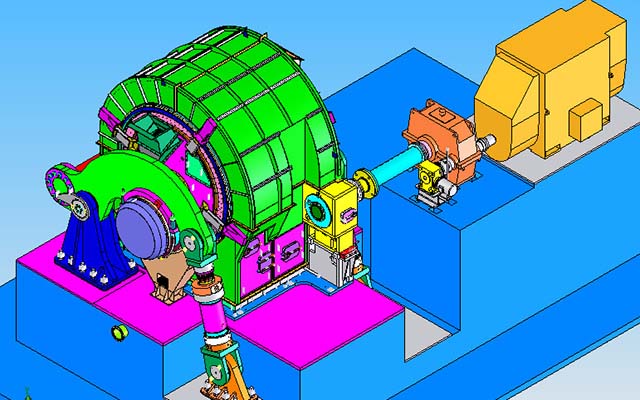

The Horomill is a kind of equipment based on the principle of material bed crushing. It cleverly combines the advantages of both ball mills and roller presses. The equipment uses moderate squeezing pressure and medium roller surface line speed to achieve extrusion and grinding of materials. This avoids the process problems that exist in vertical mills and roller presses. The Horomill is suitable for grinding materials such as cement clinker, slag, fly ash, limestone, and others. It can be used as pre-powder grinding equipment or as final grinding equipment.

Whatsapp:

+8613917653369Email:

[email protected]The pulverizing machine consists of a rotary cylinder body, a material movement control and propulsion device, and a sealing shell. The rotary cylinder body is supported on the dynamic hydraulic oil film bearing, which is driven by the transmission device. Inside the rotary cylinder, there is a wear-resistant lining plate and a pressure roller that is suspended. The hydraulic cylinder transmits the grinding pressure required by pulverized materials to the pressure roller through the pressure device. This pressure is then directly applied to the pulverized materials.

As the substances move, the grinding material inside the mill undergoes a centrifugal effect due to the pressure and centrifugal force. The material is then moved to the upper cylinder, which is installed under the scraper device. The scraping action occurs on the material that is thrown onto the material propeller by the material. The material then moves from the entry point to the outlet through a similar spiral trajectory at a set speed. During this process, the material is repeatedly crushed, pressed, split, folded, and rolled due to the function of the material bed.

Once the material completes its spiral movement inside the mill, it is scraped off by the scraping plate at the exit. The discharged material is then collected by the discharge hopper and sent to the third stage of centrifugation. To meet technological requirements and adjust the output, the speed of material propulsion can be modified by adjusting the position of the material propeller. This allows the amount of material passing through the mill to be adjusted accordingly.

The process flow above is the micro powder process of steel and iron slag, which belongs to online drying. The process is simple and the process is smooth.

| Types | Production range (tph) | ||||||||

| HRM | kw | OPC | Blended | Slag | Raw Material | ||||

| 2000 | 450 | 12 | 20 | 16 | 26 | 10 | 14 | 45 | 55 |

| 2400 | 700 | 20 | 34 | 28 | 40 | 16 | 24 | 70 | 85 |

| 2800 | 1100 | 30 | 50 | 42 | 60 | 24 | 36 | 110 | 135 |

| 3400 | 1800 | 50 | 85 | 65 | 100 | 40 | 60 | 180 | 220 |

| 3800 | 2400 | 70 | 115 | 95 | 140 | 56 | 80 | 245 | 300 |

| 4000 | 2800 | 75 | 125 | 105 | 155 | 60 | 90 | 275 | 340 |

| 4200 | 3000 | 85 | 140 | 120 | 175 | 70 | 105 | 310 | 380 |

| 4400 | 3400 | 95 | 160 | 130 | 195 | 80 | 115 | 340 | 420 |

| 4600 | 3800 | 105 | 175 | 145 | 220 | 85 | 130 | 380 | 470 |

| 4800 | 4200 | 120 | 195 | 160 | 240 | 95 | 140 | 415 | 510 |

| 5000 | 4600 | 130 | 215 | 175 | 265 | 105 | 155 | 460 | 570 |

Submit Request