Impact crushers have the advantage of high compression strength, up to 350 MPa, a large crushing ratio, and producing cubic particle sizes after crushing. They are suitable for large-scale crushing production. Our company offers both PF series and PFW series impact crushers.

Whatsapp:

+8613917653369Email:

[email protected]PF Series Impact Crusher

PF impact crusher can crush various ores and rocks (such as granite, marble, and limestone) with compressive strength up to 350MPa. This makes it widely used in the production of sand and gravel materials for constructing highways, railroads, water conservancy, electric power, and buildings.

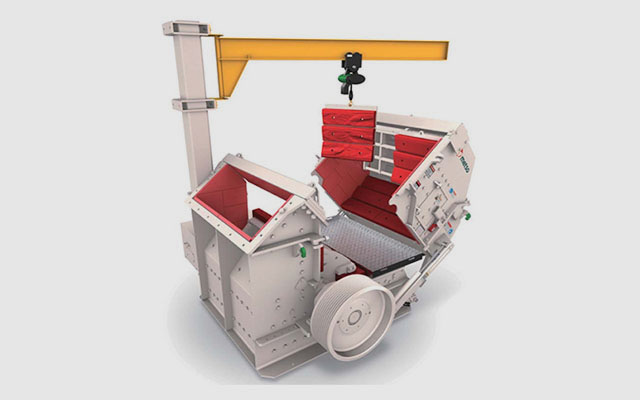

PFW Series Impact Crusher

The PFW impact crusher uses a special plate hammer fixing device, which enhances the reliability of the plate hammer. It has a hydraulic device for quickly adjusting the discharge opening size and particle size. Additionally, the two-chamber design of the PFW crusher can meet the majority of requirements for coarse, medium, and fine crushing operations.

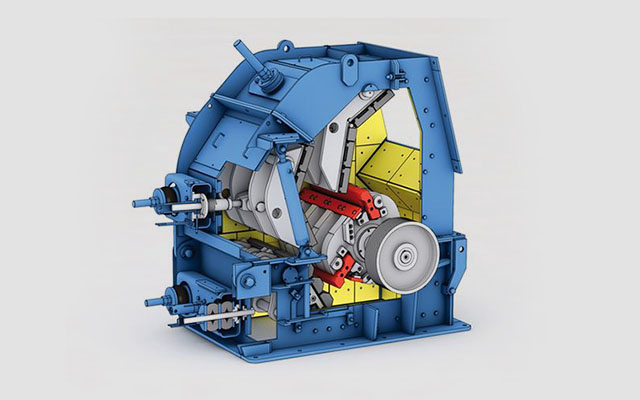

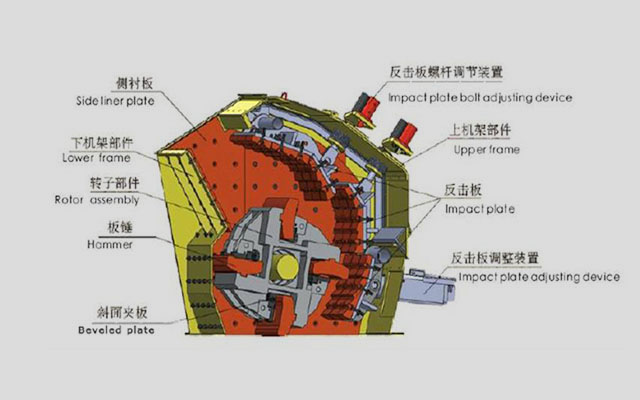

The Impact Crusher series crushes materials using impact energy. When in operation, the rotor rotates at high speed, driven by the electric motor. Material entering from the feed port is crushed by the high-speed impact of the plate hammer on the rotor. The crushed material is then further crushed by the impact on the liner, and finally discharged from the discharge port. The gap between the impact frame and rotor frame can be adjusted to change the size and shape of the material.

| Model | Rotor spec (mm) | Inlet (mm) | Maximum feeding size (mm) | Capacity (t/h) | Power(kw) |

| PF1010 | Φ1000×1050 | 400×1080 | 350 | 50-80 | 75 |

| PF1210 | Φ1250×1050 | 400×1080 | 350 | 60-120 | 110 |

| PF1214 | Φ1250×1400 | 400×1430 | 350 | 80-160 | 132 |

| PF1315 | Φ1300×1500 | 860×1520 | 350 | 120-260 | 200 |

| PF1515 | Φ1500×1500 | 1200×1520 | 950 | 220-450 | 220-315 |

| Model | Rotor spec (mm) | Inlet (mm) | Maximumfeeding size(mm) | Capacity(t/h) | Power(kw) |

| PFW1214II | Ф1150×1400 | 1100×1430 | 500 | 130-200 | 132 |

| PFW1315II | Ф1300×1500 | 1200×1530 | 600 | 180-320 | 200 |

| PFW1318II | Ф1300×1800 | 1200×1830 | 700 | 240-400 | 250 |

| PFW1415II | Ф1400×1500 | 1450×1530 | 700 | 300-480 | 250 |

| PFW1214 | Ф1150×1400 | 570×1430 | 250 | 90-170 | 132 |

| PFW1315 | Ф1150×1400 | 625×1530 | 300 | 180-270 | 200 |

| PFW1318 | Ф1150×1400 | 625×1830 | 300 | 220-300 | 250 |

| PFW1415 | Ф1150×1400 | 800×1530 | 350 | 280-350 | 250 |

Submit Request