The zinc oxide rotary kiln is a vital piece of equipment that is used for the calcination of zinc. Our state-of-the-art zinc oxide rotary kiln equipment boasts impressive processing capacity, high automation, and consistent product quality. Although the investment required may be substantial, it ensures unparalleled efficiency and excellence. Currently, this system is one of the most advanced zinc oxide processing systems available for treating zinc-leaching residue in China.

Whatsapp:

+8613917653369Email:

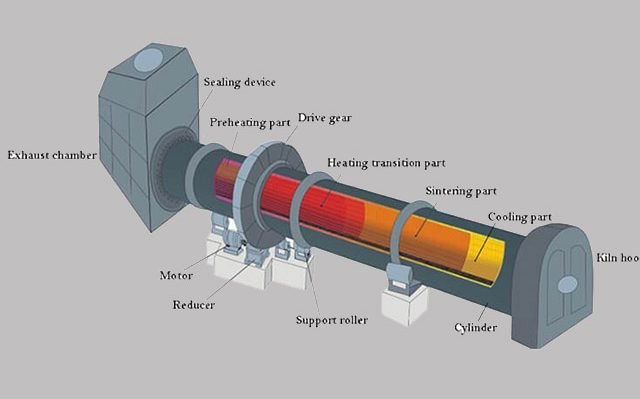

[email protected]The zinc oxide rotary kiln is a device consisting of a cylinder, a refractory lining, a transmission mechanism, a support structure, a kiln hood, a kiln tail sealing device, a fan, a combustion device, and other components. Zinc oxide powder or zinc oxide ore is added into the rotary kiln and is subjected to a thermal decomposition reaction at high temperatures, resulting in the production of zinc oxide. Although the zinc oxide rotary kiln is primarily utilized for the production of zinc oxide, it can also be utilized in other industrial processes that involve heat treatment and decomposition of solid materials, such as metal reduction, catalyst activation, and solid waste treatment.

| Spec. (m) | Diameter (m) | Length (m) | Inclination (degree) | Capacity (t/d) | Cylinder Speed (r/min) | Motor (kw) | Weight (t) |

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 |

| Φ3.0×45 | 3.0 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 201.94 |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| Φ3.0×60 | 3.0 | 60 | 4 | 800 | 0.3-2 | 100 | 310 |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| Φ4.0×56 | 4.0 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max 4.23 | 800 | 1265 |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max 5 | 950×2 | 1659 |

Submit Request