The ceramic ball mill is a new type of energy-saving ball mill developed by domestic mineral processing machinery experts combined with the latest domestic ball mill technology. It improves production capacity and crushing efficiency and expands the scope of application, from limestone to basalt, from stone production to various ores crushing.

Whatsapp:

+8613917653369Email:

[email protected]The ceramic ball mill is used for mixing and grinding materials. It ensures product uniformity and saves power, and can be used in both dry and wet conditions. The machine has different liner types and controls grinding fineness through time. It has a novel structure, is easy to operate, safe, stable, and reliable. Compared to similar products, it has a lower investment cost and saves energy and power.

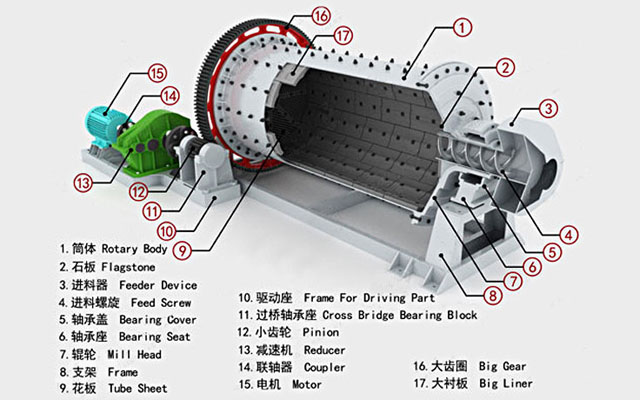

The motor drives the cylinder to rotate through the deceleration device. The lining plate brings the cylinder's crushed ore and steel balls to a certain height under friction and centrifugal force when the cylinder rotates. It is gradually crushed under the action of impact and grinding. The crushed ore is discharged out of the cylinder through the discharge part. After the discharged minerals are classified into qualified products in the spiral classifier, the coarse sand passes through the joint feeder and returns to the ball mill for further grinding. The feeder feeds continuously and evenly, the ore enters the ball mill continuously and evenly through the joint feeder, and the ground materials are continuously discharged from the ceramic ball mill. A ceramic ball mill is a grinding equipment that can work continuously 24 hours a day.

| Models | Loading Capacity (ton/time) | Cylinder speed (rpm) | Power (KW) |

| 800✖600 | 0.075 | 42 | 3 |

| 900✖1200 | 0.2 | 38.5 | 5.5 |

| 1300✖1500 | 0.5 | 33 | 7.5 |

| 1500✖1800 | 1.2 | 28.5 | 11 |

| 1800✖2000 | 1.5 | 24 | 15 |

| 2600✖2800 | 5 | 16.5 | 37 |

| 3000✖3800 | 10 | 14.5 | 55 |

| 3200✖4600 | 15 | 13.5 | 75 |

| 3400✖6600 | 18 | 13 | 135 |

Submit Request