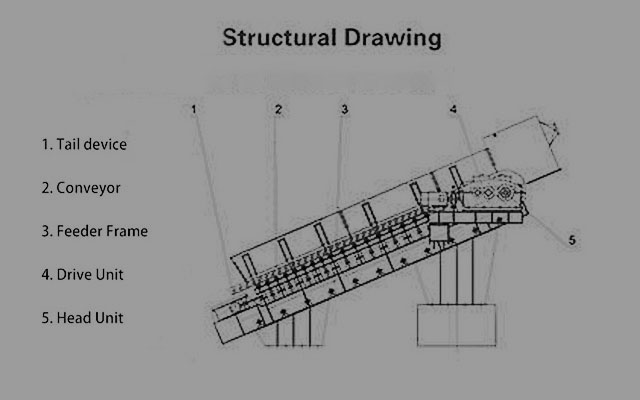

The plate feeder is a type of feeding equipment that is categorized into three types: light, medium, and heavy. It is typically used at the end of a conveyor or elevator that feeds a plant, but it can also be used to feed any other single unit. This feeding equipment is widely used in mining, metallurgy, building materials, and coal industries.

Whatsapp:

+8613917653369Email:

[email protected]

A plate feeder is used to collect ore at the bottom of the outlet of the ore bin. The ore falls onto a leakage plate fixed on the bottom of the carrier roller, which is connected to the reducer through an eccentric mechanism. The leakage plate is then lined on the motor via a coupling. When the motor runs, it drives the reducer through the coupling and makes reciprocating linear motion through the eccentric disc and the leakage plate between the rollers at the frame's bottom. This results in uniform feeding.

| Model | Width (mm) | Inclination | Feeding Capacity (t/h) | Transporting Particle Size (mm) | Transporting Velocity (m/s) |

| WB800 * 1500 | 800 | 23 | 40-70 | 350 | 0.014-0.14 |

| WB800 * 1500 | 1000 | 23 | 40-100 | 600 | 0.014-0.14 |

| WB800 * 1500 | 1250 | 23 | 40-200 | 800 | 0.014-0.14 |

| WB800 * 1500 | 1500 | 23 | 40-250 | 1200 | 0.014-0.14 |

Note: The data in this sample form is for reference selection only, and the equipment guarantee index is subject to the contract.

Submit Request