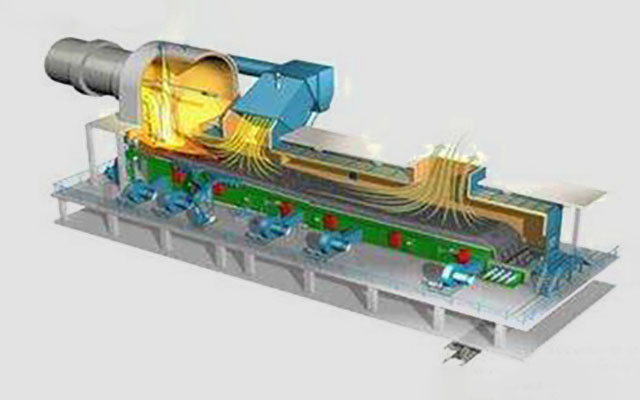

As one of the key equipment of clinker firing systems in cement production, the main role of grate coolers is to cool and convey cement clinker. At the same time, the grate cooler can also provide hot air for rotary kilns and decomposition furnaces, etc., to realize the recycling of heat energy.

Whatsapp:

+8613917653369Email:

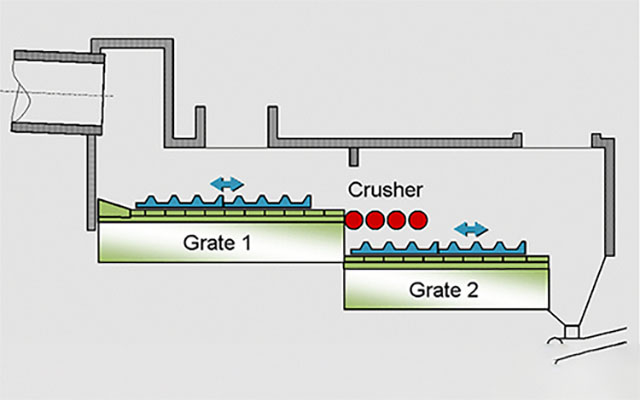

[email protected]The grate cooler is mainly composed of upper casing, lower casing, grate bed, grate bed transmission device, grate bed support device, clinker crusher, leakage zipper machine, automatic lubrication device and cooling air unit.

The cement clinker enters the inlet end of the grate cooler, and the grate's movement pushes the cement clinker from the inlet end to the outlet end. The cold air is blown from the bottom of the material bed upwards into the material layer and passes through the grate plate for sufficient heat exchange with the clinker. Under the effect of cold air, the cement clinker is gradually cooled. After cooling the clinker, the cooling air becomes hot air. The high-temperature hot air at the hot end is used as combustion air in the kiln and decomposition furnaces, and part of the hot air can also be used for drying. Hot air utilization can achieve the purpose of heat recovery, and reduce the heat consumption of the system; the excess hot air will be discharged into the atmosphere after dust collection treatment.

The cooled small pieces of clinker fall through the grate screen into the conveyor after the grate cooler; the large pieces are crushed, cooled, and remitted into the conveyor. The fine clinker and dust leak into the collecting hopper through the grate joints and grate holes of the grate bed. When the material level in the hopper reaches a certain height, the airlock valve controlled by the material level sensing system will open automatically and the leaking fines will enter the leakage zipper under the machine and be transported away. When the remaining fine material in the bucket can still seal the air lock valve, the valve plate is closed to ensure no air leakage.

| Model | Effective area (m2) | Capacity(t/d) | Note |

| LS2413 | 28 | 1000-1250 | Mechanical transmission |

| LS2717 | 39.6 | 1500-1700 | Mechanical transmission |

| LS2718 | 43.8 | 1700-1900 | Mechanical transmission |

| LS3322 | 62 | 2500-2800 | Hydraulic transmission |

| LS3323 | 65 | 2600-3000 | Hydraulic transmission |

| LS3324 | 73.8 | 2800-3300 | Hydraulic transmission |

| LS3326 | 80.5 | 3200-3500 | Hydraulic transmission |

| LS3625 | 85 | 3400-3800 | Hydraulic transmission |

| LS3925 | 90 | 3500-4000 | Hydraulic transmission |

| LS3928 | 100.3 | 4000-4500 | Hydraulic transmission |

| LS3933 | 121 | 5000-5500 | Hydraulic transmission |

| LS3936 | 134.2 | 5500-6000 | Hydraulic transmission |

| LS3938 | 140 | 5800-6300 | Hydraulic transmission |

| LS4240 | 151 | 6000-6800 | Hydraulic transmission |

| LS4842 | 187.5 | 7500-8500 | Hydraulic transmission |

| LS5142 | 200 | 8000-9600 | Hydraulic transmission |

| LS5449 | 250 | 10000-12000 | Hydraulic transmission |

Submit Request