An acidification rotary kiln is a kind of equipment commonly used in ore smelting and metallurgical industries to carry out acidizing reactions of materials, such as copper sulfate acidizing, zinc sulfate acidizing, etc. Acidizing rotary kiln is mainly used to acidify ores or concentrates containing metal components for subsequent smelting and extraction operations.

Whatsapp:

+8613917653369Email:

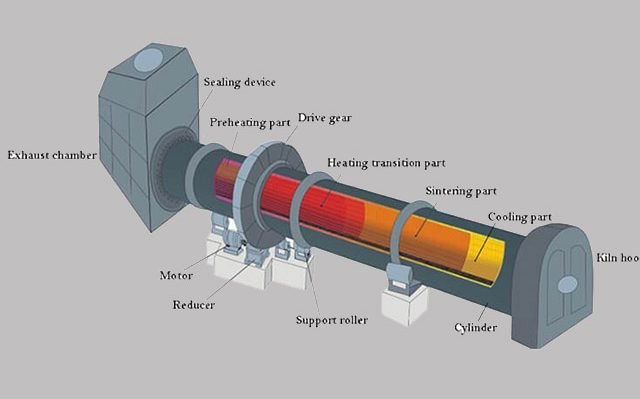

[email protected]A rotary kiln is composed of several components such as a cylinder, transmission device, support device for the tray and retaining wheel, kiln tail seal, outer jacket, combustion system, hot air duct system, kiln head cover, etc. The acidification rotary kiln exposes the material to high temperatures and oxidation through a rotating barrel and heating system, causing chemical reactions to occur. Meanwhile, the rate and extent of the acidification reaction can be adjusted by controlling the operating parameters of the rotary kiln, such as temperature, residence time, and atmosphere.

After the acidification process, the material is discharged from the rotary kiln. To prevent the entry of cold air and leakage of flue gas dust, the inlet and outlet ends of the cylinder are equipped with kiln tail and kiln head sealing devices. The jacket is equipped with special air ducts to improve the applied heat efficiency and achieve precise temperature control. The outer and inner walls of the cylinder are equipped with special anti-sticky wall devices to ensure smooth material flow.

| Model | Feed Quantity(t/h) | Revolving Speed(rpm) | Qty Of Support | Reducer Model | Motor Model | Model Power(kW) |

|---|---|---|---|---|---|---|

| φ0.8×10m | 0.2~0.5 | 0.26~2.6 | 2 | BWD4-43 | YVFE3-132S-4 | 5.5 |

| φ1.5×15m | 3~4 | 0.26~2.6 | 2 | ZSY315-71 | YVFE3-180L-4 | 22 |

| φ2.5×25m | 6~8 | 0.26~2.6 | 2 | ZSY400-40 | YVFE3-315S-6 | 75 |

| ZSY160-25 | YE3-132M-4 | 7.5 | ||||

| φ2.6×25m | 6~8 | 0.26~2.6 | 2 | ZSY400-40 | YVFE3-315S-6 | 75 |

| ZSY160-25 | YE3-132M-4 | 7.5 | ||||

| φ2.8×42m | 8~10 | 0.26~2.6 | 2 | ZSY450-40 | YVFE3-315L1-6 | 110 |

| ZSY160-25 | YE3-160M-4 | 11 | ||||

| φ3×30m | 11~12 | 0.26~2.6 | 2 | ZSY450-40 | YVFE3-315L1-6 | 110 |

| ZSY160-25 | YE3-160M-4 | 11 | ||||

| φ3.2×40m | 14~16 | 0.26~2.6 | 2 | ZSY450-35.5 | YVFE3-315L2-6 | 132 |

| ZSY160-25 | YE3-160M-4 | 11 | ||||

| φ3.5×35m | 16~18 | 0.26~2.6 | 2 | ZSY450-35.5 | YVFE3-315L2-6 | 160 |

| ZSY180-25 | YE3-180M-4 | 18.5 | ||||

| φ3.5×38m | 16~18 | 0.26~2.6 | 2 | ZSY450-35.5 | YVFE3-315L2-6 | 160 |

| ZSY180-25 | YE3-180M-4 | 18.5 | ||||

| φ3.5×50m | 16~18 | 0.26~2.6 | 2 | ZSY500-35.5 | YVFE3-355L1-6 | 220 |

| ZSY180-25 | YE3-180M-4 | 18.5 | ||||

| φ4×50m | 18~23 | 0.26~2.6 | 2 | ZSY560-35.5 | YVFE3-3552-6 | 315 |

| ZSY224-28 | YE3-200L-4 | 30 | ||||

| φ4×60m | 18~23 | 0.26~2.6 | 2 | ZSY560-35.5 | YVFE3-3552-6 | 315 |

| ZSY224-28 | YE3-200L-4 | 30 | ||||

| φ4.3×58m | 23~28 | 0.26~2.6 | 2 | ZSY630-40 | YVFE3-4001-6 | 400 |

| ZSY224-28 | YE3-200L-4 | 30 | ||||

| φ4.5×60m | 25~30 | 0.26~2.6 | 2 | ZSY710-40 | YVFE3-4002-6 | 450 |

| ZSY280-28 | YE3-225M-4 | 45 | ||||

| φ4.6×60m | 27~33 | 0.26~2.6 | 2 | ZSY710-40 | YVFE3-4002-6 | 450 |

| ZSY280-28 | YE3-225M-4 | 45 | ||||

| φ5.0×50m | 33~35 | 0.26~2.6 | 2 | ZSY710-40 | YVFE3-4002-6 | 450 |

| ZSY280-28 | YE3-225M-4 | 45 | ||||

| φ5.4×56m | 40~45 | 0.26~2.6 | 2 | MH3S230HB40 | YVFE3-4501-6 | 560 |

| ZSY280-28 | YE3-225M-4 | 45 |

Submit Request