The fly ash ball mill is an essential piece of equipment used for crushing and grinding materials. It is suitable for both dry and wet grinding of various ores and other materials, making it widely used in industries such as ore beneficiation, building materials, and chemical engineering.

Whatsapp:

+8613917653369Email:

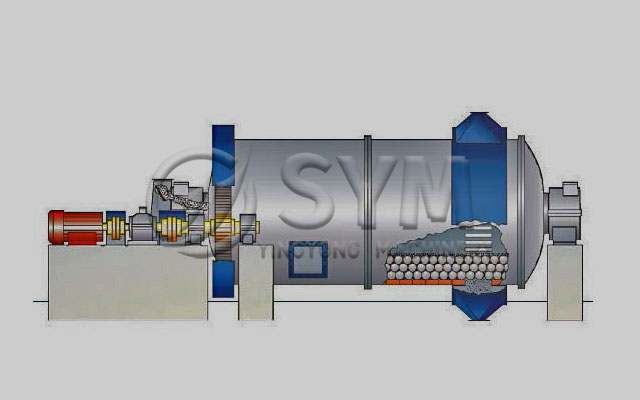

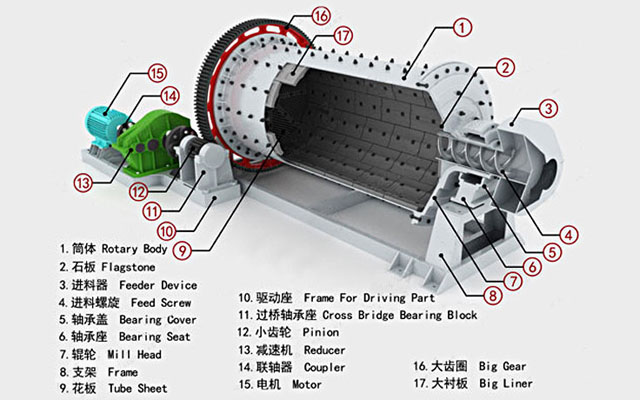

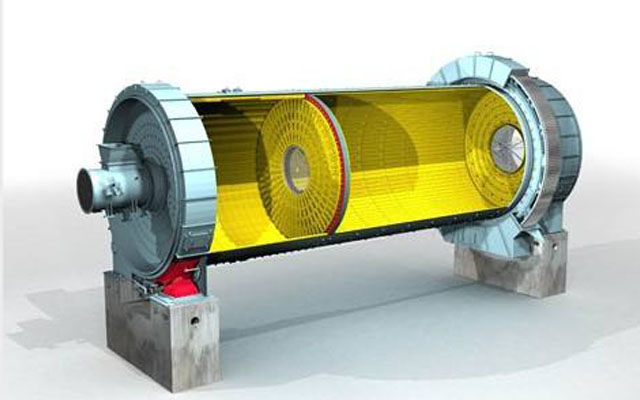

[email protected]The fly ash ball mill consists of several parts, including the feeding, discharging, rotating, and transmission parts ( reducer, small driving gear, motor, and electrical control). The hollow shaft is made of cast steel and the lining can be replaced. The rotary gear is processed by casting hobbing, and the cylinder is lined with a wear-resistant liner that provides good wear resistance.

The fly ash ball mill's main engine includes a cylinder lined with wear-resistant materials, bearings, and drive components such as motors, transmission gears, pulleys, and V-belts, ensuring smooth operation.

The material is fed into the cylinder of the ball mill through the feeding end, based on its size. As the cylinder starts rotating, the grinding media sticks to the lining plates near the cylinder. Due to the influence of inertia, centrifugal force, and friction, the grinding media reaches a certain height as the cylinder rotates. At this point, the grinding media falls and crushes the materials within the cylinder.

| Spec./m | Speed(r/min) | Easy Grinding ( Capacity t/h ) | Hard Grinding ( Capacity t/h ) | Grinding Media Loading (t) | Main Motor(KW) | Main Reducer | Weight ( t ) |

| Φ1.83x7.0 | 23.8 | 12-13 | 5-6 | 22 | 245 | ZD60 | 43.5 |

| Φ1.83x8.0 | 23.8 | 15-16 | 7-8 | 26 | 280 | ZD60 | 46 |

| Φ1.83x9.5 | 24.1 | 16-17 | 11-12 | 31 | 355 | ZD70 | 56 |

| Φ2.1 x8.5 | 23.9 | 18-19 | 14-15 | 36 | 475 | ZD70 | 66 |

| Φ2.1 x10 | 23.9 | 19-20 | 15-16 | 42 | 475 | ZD70 | 70 |

| Φ2.2x9.0 | 21.5 | 19-20 | 15-16 | 40 | 475 | ZD70 | 69 |

| Φ2.2x9.5 | 21.5 | 21-22 | 17-18 | 41 | 475 | ZD70 | 74 |

| Φ2.2x11 | 21.5 | 23-24 | 18-19 | 50 | 570 | ZD80 | 109 |

| Φ2.2x 13 | 21.5 | 25-26 | 20-21 | 58 | 630 | ZD80 | 114 |

| Φ 2.4x12 | 20.3 | 29-30 | 22-23 | 63 | 800 | MBY630 | 128 |

| MBY710 | |||||||

| Φ2.4x13 | 20.3 | 32-33 | 25-26 | 68 | 800 | MBY630 | 138 |

| MBY710 | |||||||

| Φ2.6x13 | 19.7 | 37-38 | 30-31 | 82 | 1000 | MBY800 | 158 |

| Φ3.2x 13 | 17.8 | 55-60 | 43-48 | 128 | 1600 | MBY900 | 230 |

Submit Request