Input Size: ≤38mm

Capacity:31.7-119.7 T/H

Material: The coal vertical mill can be used for grinding bituminous coal, anthracite, lignite, petroleum coke, coke, asphalt and other materials; limestone, lime, barite, talc, gypsum, cement raw material, slag, cement and other industrial grinding fields.

Application field: It is a kind of grinding equipment integrating drying, grinding and powder selection, which is widely used in coal chemical, thermal power, steel and non-metallic mineral grinding fields.

Whatsapp:

+8613917653369Email:

[email protected]High-efficiency HP bowl coal mill is a new type of energy-saving product launched by our company, which aims to solve the technical problems of low output and high energy consumption of industrial mills. It is developed on the basis of traditional HP vertical medium-speed coal mills. The basic frame and roller loading method have been retained while enhancing the roller structure and dynamic separator. This improvement significantly reduces the circulation rate of pulverized coal, increases the mill's output, and reduces the ventilation resistance of the system. These advantages are clearly evident when compared to conventional HP pulverizers.

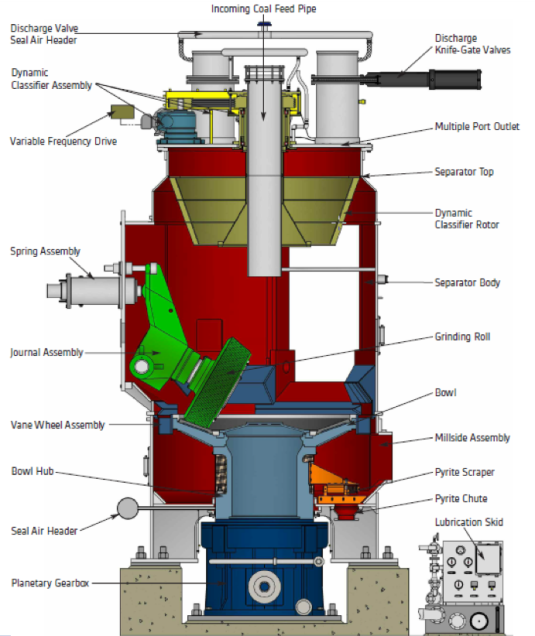

The high-efficiency HP bowl coal mill is comprised of several components, including a falling coal pipe, a gate valve used for exporting pulverized coal, a dynamic separator device, a spring-loaded device, a high-efficiency roller, a bowl-grinding device, and stone coal collection devices. It also includes transmissions, bases, housings, and other components. The dynamic separator is an energy-efficient device that helps select powder.

The roller device is responsible for grinding and crushing the material. The grinding device is securely mounted on the output shaft of the speed reducer, serving as the area where the roller exerts force on the material. A spring-loaded device plays a crucial role by providing grinding pressure to the roller, ensuring sufficient force to crush the material effectively.

The electric motor drives the grinding disc through the reducer, so that the material falls on the center of the grinding disc from the inlet, while the hot air enters the mill from the inlet. Under the action of centrifugal force, the material is brought up to the edge of the grinding disc by the high-speed airflow of the wind ring. The large particles fall directly to the grinding disc for regrinding.

As the airflow carries the material into the upper separator, the coarse powder falls from the cone bucket onto the grinding disc for regrinding under the rotating rotor's action. The qualified fine powder exits the mill along with the airflow and is collected by the dust collection device as the final product. During the process, materials containing moisture are dried as they come into contact with hot gas. Adjusting the hot air temperature allows for meeting the requirements of different humidity materials and achieving the desired product moisture. The HP bowl coal mill can attain the necessary fineness and coarseness for different products by adjusting the separator.

| model | Disc diameter(mm) | Roller diameter(mm) | Input(mm) | Capacity(t/h) | Air volume(t/h) | Disc speed(r/min) | Power(Kw) | Weight(T) |

| HP683 | 1900 | 1100 | ≤38 | 31.7 | 36.1 | 45.2 | 225~260 | 75 |

| HP703 | 1900 | 1100 | ≤38 | 34.7 | 39.5 | 45.2 | 225~260 | 75 |

| HP723 | 1900 | 1100 | ≤38 | 37.8 | 42.7 | 45.2 | 225~260 | 75 |

| HP743 | 1900 | 1100 | ≤38 | 41.1 | 46.5 | 45.2 | 225~260 | 75 |

| HP763 | 2100 | 1200 | ≤38 | 44.6 | 52.4 | 41.3 | 260~300 | 90 |

| HP783 | 2100 | 1200 | ≤38 | 48.2 | 54.4 | 41.3 | 260~300 | 90 |

| HP803 | 2100 | 1200 | ≤38 | 52.4 | 59.3 | 41.3 | 260~300 | 90 |

| HP823 | 2200 | 1300 | ≤38 | 56.0 | 65.3 | 38.4 | 345~400 | 115 |

| HP843 | 2200 | 1300 | ≤38 | 59.9 | 68 | 38.4 | 345~400 | 115 |

| HP863 | 2200 | 1300 | ≤38 | 63.5 | 72.1 | 38.4 | 345~400 | 115 |

| HP883 | 2400 | 1400 | ≤38 | 67.3 | 76.7 | 35 | 400~450 | 135 |

| HP903 | 2400 | 1400 | ≤38 | 71.3 | 83 | 35 | 400~450 | 135 |

| HP923 | 2400 | 1400 | ≤38 | 75.1 | 85.5 | 35 | 400~450 | 135 |

| HP943 | 2400 | 1400 | ≤38 | 79.1 | 89.8 | 35 | 400~450 | 135 |

| HP963 | 2600 | 1500 | ≤38 | 82.6 | 94.7 | 33 | 450~520 | 140 |

| HP983 | 2600 | 1500 | ≤38 | 86.2 | 98 | 33 | 450~520 | 140 |

| HP1003 | 2600 | 1500 | ≤38 | 89.8 | 102.1 | 33 | 450~520 | 140 |

| HP1023 | 2800 | 1600 | ≤38 | 95.8 | 108.9 | 30 | 520~700 | 160 |

| HP1043 | 2800 | 1600 | ≤38 | 101.8 | 115.7 | 30 | 520~700 | 160 |

| HP1063 | 2800 | 1600 | ≤38 | 110.7 | 125.9 | 30 | 520~700 | 160 |

| HP1103 | 2800 | 1600 | ≤38 | 119.7 | 136.1 | 30 | 520~700 | 160 |

Submit Request