Material: gypsum, calcite, bauxite, talc, limestone, marble, potassium feldspar, dolomite, kaolin, bentonite, wheat meal stone, iron oxide red, granite, iron ore, etc.

Application field: Raymond mill is widely used in calcium carbonate crushing and processing, gypsum powder processing, power plant desulfurization, non-metallic mineral powder making and coal powder preparation.

Whatsapp:

+8613917653369Email:

[email protected]With a simple structure and convenient operation, Raymond mills are suitable for processing various non-flammable and explosive minerals with Mohs hardness below grade seven and humidity below 6%. Also, Raymond Mill has the characteristics of low energy consumption and a good grinding effect and is widely used in metallurgy, building materials, the chemical industry, mining, and other fields.

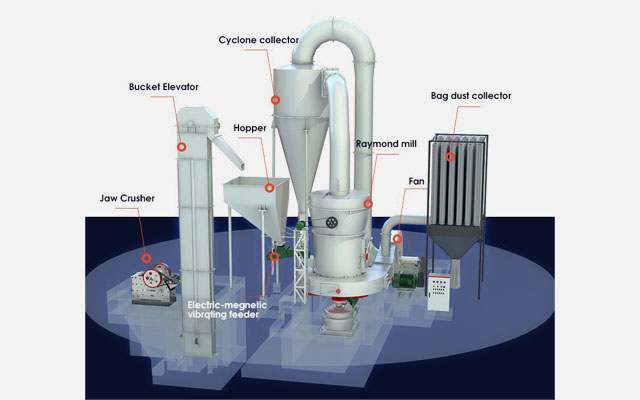

Raymond roller mill is mainly composed of main machine, analyzer, blower, finished cyclone separator, pipeline device, motor, etc. The auxiliary equipment includes Raymond mill, dustpan elevator, electromagnetic vibrating feeder, electric control cabinet and other components. The Raymond mill crushes large raw materials into the desired particle size and is then transported to the storage bin through an elevator.

Subsequently, the vibrating feeder evenly feeds the material into the grinding chamber. The material is ground between the grinding rollers and the grinding ring, and the fan brings the powder to the analyzer for classification. The fineness of the powder meets the requirements, enters the large cyclone collector through the pipeline for separation and collection, and finally discharges the finished product.

The shovel system is key in the main machine's working process. Blade scoops up the material and throws it into the gap between the grinding roller rings to form a cushion layer. So, the material is crushed by the extrusion force of the rotating grinding roller to achieve the goal of crushing.

Submit Request