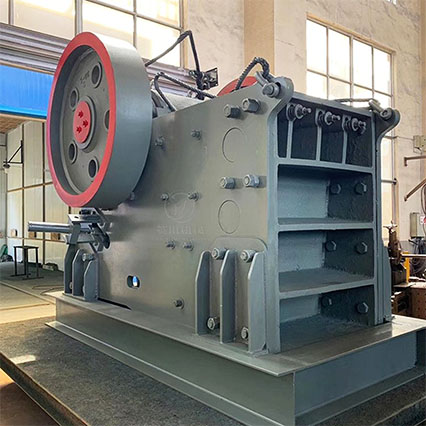

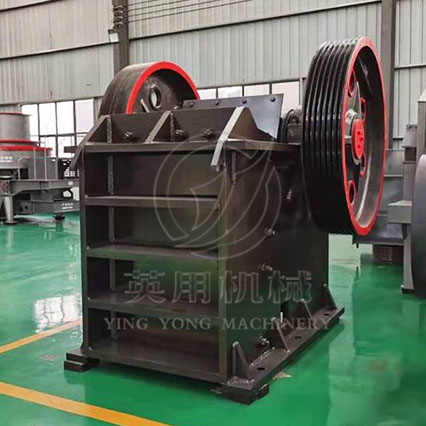

The Jaw Crusher can crush all kinds of minerals and rocks with a compressive strength of less than 320 MPa. It is widely used in mining, building materials, chemical industries, metallurgy, etc. This jaw crusher machine is suitable for primary and secondary crushing.

Whatsapp:

+8613917653369Email:

[email protected]PEW jaw crusher is a new type of crushing machine. The PEW Jaw Crusher's V-shaped crushing chamber and toothed guard make the actual size of the feed material consistent with the ideal size, effectively expanding the crushing space. In addition, the material does not accumulate in the crushing chamber so it can optimize the crushing ratio and output.

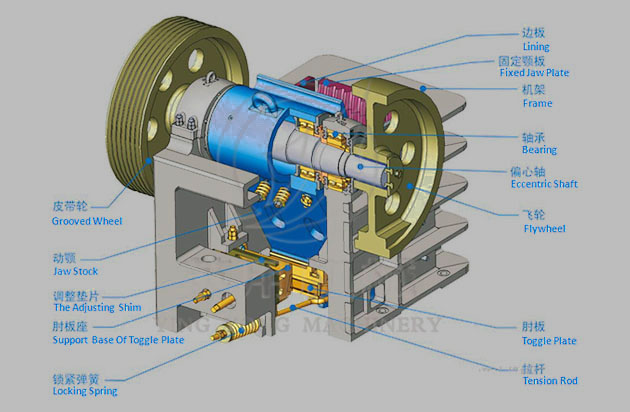

The motor powers Jaw Crusher. Through the motor pulley, the eccentric shaft is driven by the V-belt and the sheave so that the movable jaw reciprocates along the predetermined tracks to crush materials inside the crushing cavity. After being processed and reaching the standard, materials would be discharged from the lower discharge opening.

| Model | Inlet Size (mm) | Maximum Feeding Size (mm) | Adjustable Range of Output (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) |

| PE250×400 | 250×400 | 200 | 20-50 | 5-20 | 15 | 2.9 |

| PE400×600 | 400×600 | 350 | 40-100 | 15-60 | 30-37 | 6.8 |

| PE500×750 | 500×750 | 425 | 50-100 | 40-100 | 45-55 | 11.2 |

| PE600×900 | 600×900 | 480 | 65-160 | 60-140 | 55-75 | 16.5 |

| PE750×1060 | 750×1060 | 630 | 80-150 | 80-230 | 90-110 | 29 |

| PE900×1200 | 900×1200 | 750 | 95-165 | 140-320 | 110-132 | 54.5 |

| PE1000×1200 | 1000×1200 | 850 | 105-185 | 180-400 | 160-200 | 56.5 |

| PE1200×1500 | 1200×1500 | 1020 | 150-300 | 250-800 | 220-250 | 99.6 |

| PEX150×750 | 150×750 | 125 | 12-45 | 5-16 | 15 | 3.8 |

| PEX250×750 | 250×750 | 210 | 25-60 | 10-40 | 22-30 | 5 |

| PEX250×1000 | 250×1000 | 210 | 25-60 | 15-50 | 30-37 | 6.8 |

| PEX250×1200 | 250×1200 | 210 | 25-60 | 20-60 | 37-45 | 8.5 |

| PEX400×1200 | 400×1200 | 320 | 35-95 | 28-95 | 45-55 | 11.7 |

| Model | Inlet size(mm) | Maximum Feeding Size(mm) | Adjustable Range of Output (mm) | Capacity (t/h) | Motor Power(kw) | Weight (t) |

| PEW250X1000 | 250X1000 | 220 | 20-40 | 15-50 | 330 | 30 |

| PEW250X1200 | 250X1200 | 220 | 20-50 | 37 | ||

| PEW400X600 | 400X600 | 350 | 35-85 | 15-70 | 250 | |

| PEW760 | 760X1100 | 640 | 75-200 | 150-350 | 270 | 110 |

| PEW860 | 860X1100 | 720 | 100-225 | 200-500 | 240 | 132 |

| PEW1100 | 1100X1200 | 930 | 150-275 | 300-650 | 210 | 185 |

Submit Request