An autogenous tumbling mill is a grinding machine that can process raw ore from the quarry or ore that has been coarsely crushed without the need for additional media. The key advantage of this mill is its large crushing ratio. It can handle feed sizes up to 300-400mm or even larger, while the minimum discharge size can reach 0.1mm. This results in a crushing ratio of 3000-4000. In comparison, the ball mill usually has a smaller feed size of 20-30mm, and the product size is typically between 0-3mm.

Whatsapp:

+8613917653369Email:

[email protected]The wet autogenous grinding system is composed of a wet autogenous mill, particle size control operation, secondary grinding equipment, and processing facilities for difficult-to-grind particle grades. Usually, the minerals are fed into the rod mill in a specific size ratio. The autogenous mill can grind the material to a size of 0.074mm instantly, and its content accounts for more than 20% to 50% of the total product. The crushing ratio can reach 4000-5000, more than ten times higher than that of ball and rod mills.

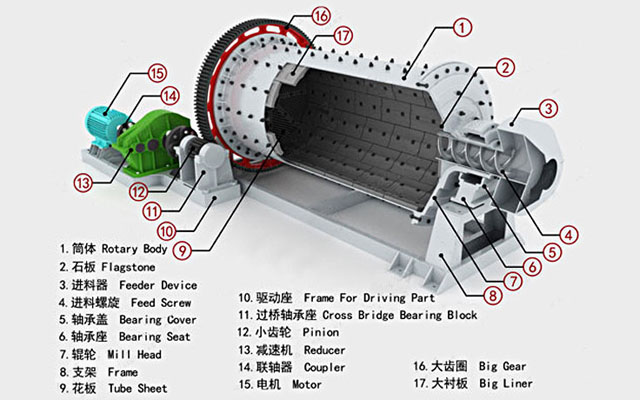

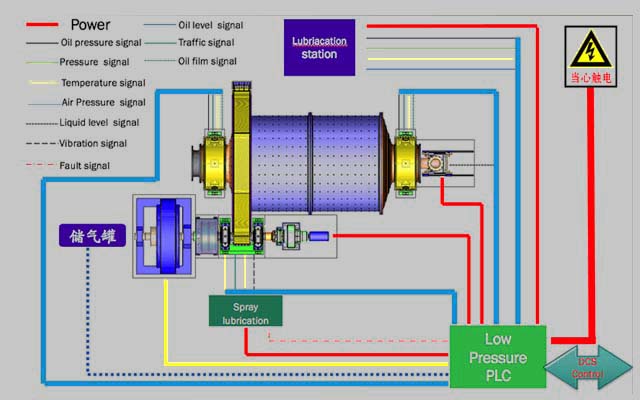

An autogenous mill is a new type of ore-grinding equipment with crushing and grinding functions. It uses the material itself as the medium to achieve crushing through mutual impact and grinding. The autogenous mill has two driving modes: variable and fixed speed, with different power levels. Some autogenous mills are also equipped with micro-motion devices. It is equipped with a cylinder jacking device for easy maintenance; for large mills, to eliminate the static resistance moment when starting, modern advanced technologies such as hydrostatic bearings are used to ensure the safe operation of the autogenous mill.

| model ( Length can be customized) | (mm) cylinder diameter | (mm) cylinder length | (m³) practical volume | (t) loading capacity | (r/min) rotating speed | (kw) power |

| MA-40(AG-40) | 4000 | 1400~3600 | 17~42 | 2~6 | 16.2 | 220~540 |

| MA-45(AG-45) | 4500 | 1600~4100 | 24~61 | 3~9 | 15.3 | 320~830 |

| MA-50(AG-50) | 5000 | 1800~4500 | 34~83 | 5~12 | 14.5 | 500~1200 |

| MA-55(AG-55) | 5500 | 1800~5000 | 42~112 | 6~16 | 13.8 | 630~1700 |

| MA-61(AG-61) | 6100 | 2400~5500 | 69~152 | 10~21 | 13.1 | 1050~2400 |

| MA-67(AG-67) | 6700 | 2600~6000 | 93~201 | 13~28 | 12.5 | 1500~3300 |

| MA-73(AG-73) | 7300 | 2800~6600 | 120~264 | 17~37 | 12.0 | 2000~4500 |

| MA-80(AG-80) | 8000 | 3200~7200 | 160~347 | 22~48 | 11.4 | 2800~6200 |

| MA-86(AG-86) | 8600 | 3400~7700 | 197~429 | 27~60 | 11.0 | 3500~7900 |

| MA-92(AG-92) | 9200 | 3700~8300 | 246~530 | 34~74 | 10.7 | 4500~10000 |

| MA-98(AG-98) | 9800 | 3900~8800 | 296~640 | 41~89 | 10.3 | 5600~12500 |

| MA-104(AG-104) | 10400 | 4200~9400 | 359~770 | 50~107 | 10.0 | 7000~15400 |

| MA-110(AG-110) | 11000 | 4400~9900 | 422~909 | 59~127 | 9.8 | 8400~19000 |

| MA-116(AG-116) | 11600 | 4600~10400 | 492~1064 | 69~148 | 9.5 | 10000~22000 |

| MA-122(AG-122) | 12200 | 4900~11000 | 580~1246 | 81~174 | 9.2 | 12000~27000 |

Submit Request