The intelligent ore sorting system is a fully automatic equipment that utilizes machine vision, deep learning, automation control, mechatronics integration, high-performance computing, and big data technologies.

Whatsapp:

+8613917653369Email:

[email protected]Mineral Intelligent Ore Sorting System

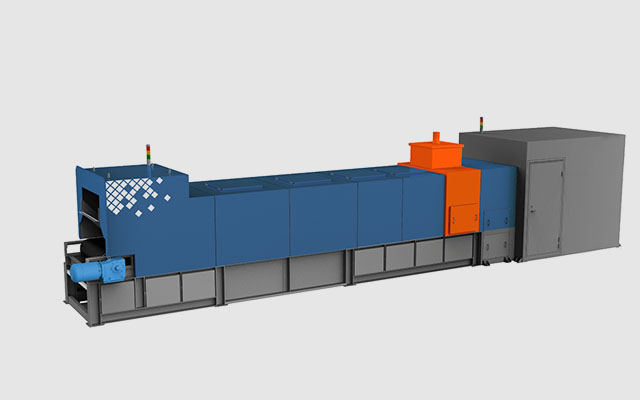

The X-ray sorting machine is a fully automatic equipment that utilizes machine vision, deep learning, automation control, mechatronics integration, high-performance computing, and big data technologies. It imitates human visual perception and brain function by using spectral imaging to differentiate the surface corrosion color, texture, fluorescence, energy spectrum, X-ray transmittance, and other features. The machine can quickly and accurately analyze qualitative and quantitative ore and select the desired ore.

Application Range

Non-ferrous metal ores: antimony, gold, copper, lead, zinc, tungsten, molybdenum, tin, nickel, vanadium, titanium, etc.

Ferrous metal ores: wolfram, iron, manganese, chromium, etc.

Precious metals: gold, silver, etc.

Fluorescent ore: scheelite, fluorite, calcite, Malayite, Zircon, lepidolite, dolomite, stratocite, icelandite, opal, massive fluorite, diamond, etc.

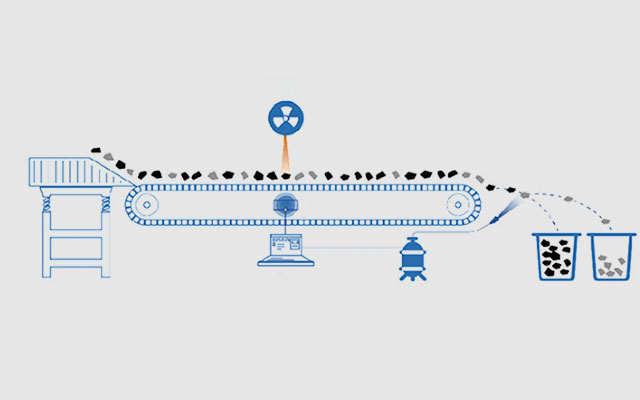

The lump of coal or ore block is evenly distributed by the feeding belt and then transferred by the conveyor belt to the X-ray recognition system.

The ore sorting machine utilizes XRT (X-ray transmission imaging) technology to automatically collect X-ray images of clean coal and gangue or high/low-grade mineral blocks and identify them.

The ore sorting system integrates high-speed computing units and high-pressure gas jet devices to sort mineral blocks automatically based on image recognition results.

| Product Model | MS1200K | MS2000K |

| Applicable particle size (mm) | 300-50 | |

| Capacity (t/h) | 100 | 200 |

| Equipment size (m) | 12.3 (length) x2.8 (width) x2.9 (height) | 12.5 (length) x3.6 (width) x3 (height) |

| Machine power (kW) | 40 | 65 |

| Equipment voltage and frequency | AC380V/660V/1140V,50Hz | |

| Air supply pressure (MPa) | 0.55-0.8 | |

| Ambient temperature (°C) | -15-+40 | |

| Staff MemberAnnual absorbed dose (mSv/year) | ≤1 | |

| Boundary dose rate (uSv/h) | ≤1, @10cm on the surface of the equipment shell | |

MS-K series coal gangue intelligent separator is a fully automatic intelligent mineral sorting equipment independently developed and manufactured by Tsinghua Tongfang Co., Ltd. for the coal series and kaolin sorting industry.

The equipment has the characteristics of high sorting accuracy, large processing capacity, environmental protection, safety and stability, etc. It can effectively replace the existing manual sorting method and improve the comprehensive utilization rate of coal gangue resources.

The equipment mainly uses XRT technology and integrates machine vision technology to automatically identify coal gangue within a specific particle size range. It distinguishes kaolin and waste stones and uses an array of high-pressure air jets for individual sorting, thereby achieving the goal of intelligent sorting.

Submit Request