The high-pressure roller press is a new type of energy-saving grinding equipment for cement production. It can replace traditional ball mill pre-grinding systems, reducing energy consumption, steel consumption, and working noise. It’s suitable for new plant construction and can increase output by 30% to 50% for old plants.

Whatsapp:

+8613917653369Email:

[email protected]By using the roller press for extrusion, the material can be divided into 20% to 35% fines of 0.08mm and 65% to 85% particles less than 2mm. The particles' internal structure is cracked, improving grindability and efficiency.

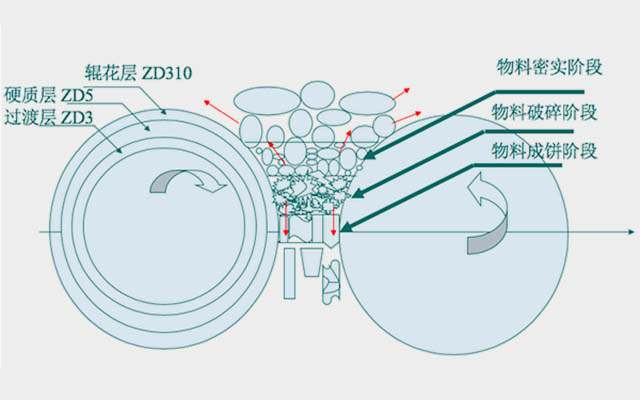

To enhance HPGR's wear resistance, the roller surface of the roller press is usually treated using a thermal overlay welding method. This design facilitates easier maintenance of the wear-resistant layer, thereby extending the equipment's lifespan. Overall, the hpgr mill is an efficient and energy-saving cement grinding equipment, making it a technology worth adopting for cement manufacturers.

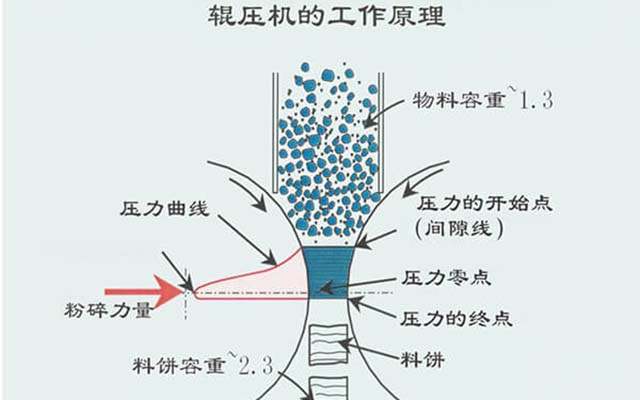

The roller press is a mechanical equipment designed based on the principle of material bed grinding. Its main characteristics include high pressure, full speed, full material, and bed material crushing. It consists of two counter-rotating squeezing rollers, one fixed and one movable. The material is fed into the roller press in a full material state from above, and then continuously conveyed between the rollers. Under the high pressure of 100-150 MPa, it forms a compacted cake, which is ultimately discharged from the bottom of the machine. The discharged cake contains a certain proportion of fine-grained finished products, while non-finished particles develop numerous internal cracks, thereby improving the material's grindability and facilitating the reduction of energy consumption in the further crushing process.

| Models | Capacity(t/h) | Motor (kW) | Linear Velocity(m/s) |

| 100-60 | 105~150 | 2×(315) | 1.36 |

| 120-45 | 100~140 | 2×220 | 1.38 |

| 120-80 | 240~300 | 2×450 | 1.31 |

| 140-80 | 340~400 | 2×560 | 1.47 |

| 140-100 | 400~480 | 2×630 | 1.48 |

| 140-110 | 500~600 | 2×710 | 1.6 |

| 140-140 | 550~630 | 2×800 | 1.48 |

| 180-170 | 900~1000 | 2×1400 | 1.7 |

Submit Request