Capacity:1000-12000t/h

Product Specifications:Φ3.2×50 – Φ6.2×96

Material: limestone, clay, slag, fly ash

Application fields: cement rotary kilns are used for cement production, lime production, metallurgical industry, petrochemical and waste treatment, etc.

Whatsapp:

+8613917653369Email:

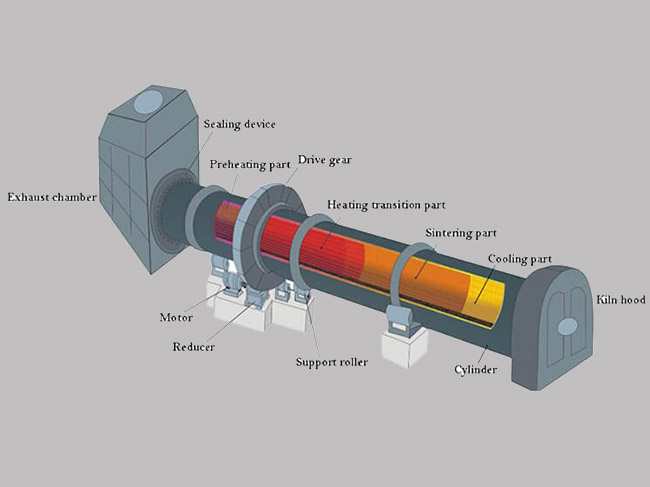

[email protected]The cement rotary kiln is a vital piece of equipment used in the cement production process. It is the primary tool in both dry and wet production lines for manufacturing high-quality cement clinker. The rotary cement kiln operates by heating limestone, clay, and other materials at high temperatures to produce the desired clinker. Our cement rotary kilns are designed with advanced features to ensure reliable performance and provide efficient, sustainable, and eco-friendly solutions for cement production.

During the cement production process, raw materials are fed through the kiln head and enter the furnace chamber of the rotary kiln. Inside the furnace chamber, the raw materials undergo a chemical reaction and exchange heat with fuel gas to gradually transform into clinker. The clinker is then discharged from the kiln tail. The rotary kiln is driven by the main engine and reducer. During this process, the fuel in the combustion unit is burned to produce high-temperature gas to evenly heat the raw material. This step is crucial in cement production. The cooling unit is used to quickly cool the clinker to prevent excessive sintering. The production process is automatically monitored and regulated by the control system to ensure stable and efficient production.

| Specifications | Capacity | Kiln Speed | Main Motor (KW) | Main Reducer | Weight | |

| m | t/d | r/min | Models | kw | Models | t |

| Φ3.2×50 | 1000 | 0.36~3.57 | ZSN4-280-091B | 160 | NZS995-40 | 259 |

| Φ3.3×50 | 1200 | 0.36~3.57 | ZSN4-280-091B | 160 | NZS995-40 | 266 |

| Φ3.5×52 | 1500 | 0.35~3.51 | ZSN4-315-082 | 190 | NZS995-25 | 318 |

| Φ3.5×54 | 1500 | 0.41~4.06 | ZSN4-315-072 | 250 | ZSY560-40 | 327 |

| Φ4.0×60 | 2500 | 0.41~4.07 | ZSN4-355-092 | 315 | YNS1110-22.4V | 446 |

| Φ4.2×60 | 3000 | 0.4~3.98 | ZSN4-355-12 | 375 | JH560-SW-28 | 491 |

| Φ4.3×60 | 3200 | 0.4~4.0 | ZSN4-355-12 | 400 | YNS1400-31.5 | 536 |

| Φ4.3×62 | 3200 | 0.4~4.0 | ZSN4-355-12 | 420 | YNS1400-31.5VIBL | 547.5 |

| Φ4.3×64 | 3500 | 0.4~4.0 | ZSN4-355-12 | 420 | YNS1400-31.5VIL | 552 |

| Φ4.3×66 | 3500 | 0.4~4.0 | ZSN4-355-12 | 450 | YNS1400-31.5VIBL | 560 |

| Φ4.8×74 | 5000 | 0.35~4.0 | ZSN4-400-092 | 630 | JH710c-SW305-40 | 859 |

| Φ5.0×74 | 6000 | 0.35~4.0 | ZSN4-450-092 | 710 | JH800c-SW306-28 | 877 |

| Φ5.6×87 | 8000 | 0.35~4.0 | ZSN4-450-12 | 800 | JH900c-SW305-25 | 1201 |

| Φ6.0×95 | 10000 | 0.35~4.0 | ZSN4-500-092 | 950×2 | JH900c-SW305-28 | 1580 |

| Φ6.2×96 | 12000 | 0.35~4.0 | ZSN4-560-092 | 1100×2 | JH900c-SW305-28 | 1730 |

Submit Request