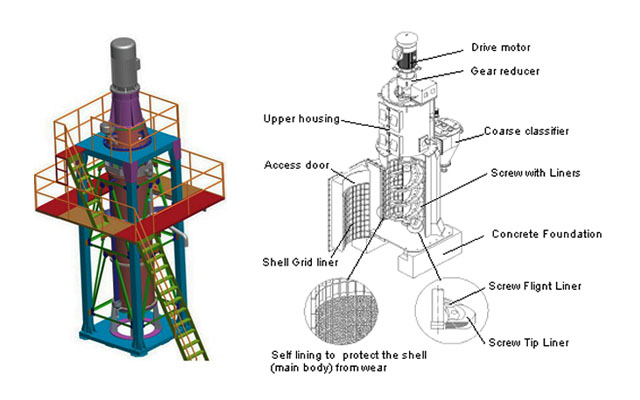

The VTM series tower mill is a newly developed wet fine grinding equipment designed to address the issues of high energy consumption and high media consumption common in existing ball mill grinding operations. The tower vertical mill is similar to a ball mill, with the only difference being that it has a vertical cylinder instead of a horizontal one.

Whatsapp:

+8613917653369Email:

[email protected]When compared to ball mills, the tower mill offers several advantages. Firstly, the larger contact area between the grinding media and the material, results in higher grinding intensity. Secondly, it consumes significantly less power per unit of product, thus achieving energy savings of over 30%. This, in turn, greatly reduces production costs.

The barrel of the stirred mill is equipped with a stirring device and ball media (e.g. ceramic, glass, and steel balls). The stirring device rotates at a low speed to make the ball media rise slowly and then fall from the highest point to move downward. This process is subject to the action of centrifugal force, gravity, and sassafras force, resulting in the crushing media and materials to achieve an orderly way of movement cycle and macroscopic force force balance.

The grinding media rotates while undergoing an up-and-down cyclic motion. Under the strong pressure, grinding force, and shear stress of the grinding media, the material is crushed. Qualified material rises with the conveying medium and is screened and then self-flowing from the top of the tower mill. There is a high falling degree between the grinding media and the material, resulting in minimal collisions. The entire rotating part is balanced in macroscopic force, resulting in low stress on the support system and reduced energy consumption of the bearings.

The tower mill is a versatile machine that can be used in various applications due to its low mixing speed, absence of moving mechanical parts, and orderly rolling of the mixing medium. It is relatively easy to achieve internal grading and reduce over-crushing with the tower mill, as the fine materials can reach the discharge port easily.

| Model | Power(kw) | Effective volume (m³) | Medium filling capacity(t) | Production capacity (t/h) | Length × width × height(m) |

| VTM-30 | 30 | 2.76 | 11-14 | 1-3 | 1.5×1.7×7.2 |

| VTM-50 | 50 | 2.76 | 11-14 | 2-4 | 1.5x1.7x7.3 |

| VTM-75 | 75 | 5.39 | 19-25 | 3-6 | 1.8x2.0x7.9 |

| VTM-100 | 100 | 7.66 | 24-33 | 4-8 | 2.1x2.3x8.7 |

| VTM-120 | 120 | 7.66 | 24-33 | 5-10 | 2.1x2.3x8.9 |

| VTM-150 | 150 | 11.45 | 27-41 | 6-13 | 2.3x2.5x9.2 |

| VTM-200 | 200 | 16.56 | 39-56 | 8-17 | 2.7x2.9x10.0 |

| VTM-250 | 250 | 16.56 | 39-56 | 9-21 | 2.7x2.9x10.3 |

| VTM-300 | 300 | 21.62 | 51-73 | 11-25 | 2.9x3.1x10.8 |

| VTM-400 | 400 | 27.37 | 64-92 | 16-36 | 3.2x3.4x11.5 |

| VTM-500 | 500 | 31.57 | 74-107 | 20-45 | 3.4x3.6x12.0 |

| VTM-600 | 600 | 36.08 | 85-122 | 25-55 | 3.6x4.0x12.7 |

| VTM-750 | 750 | 45.99 | 108-155 | 31-69 | 4.0x4.3x13.2 |

| VTM-800 | 800 | 45.99 | 108-155 | 33-74 | 4.0x4.3x13.5 |

| VTM-950 | 950 | 57.10 | 134-193 | 39-88 | 4.3x4.5x13.9 |

| VTM-1120 | 1120 | 66.22 | 156-224 | 46-103 | 4.6x4.8x14.4 |

| VTM-1250 | 1250 | 72.68 | 171-245 | 52-115 | 4.7x4.9x14.8 |

| VTM-1400 | 1400 | 79.44 | 187-268 | 58-129 | 4.9x5.0x15.1 |

| VTM-1500 | 1500 | 86.5 | 204-292 | 62-138 | 5.0x5.2x15.4 |

| VTM-1600 | 1600 | 86.5 | 204-292 | 66-148 | 5.0x5.2x15.7 |

| VTM-1800 | 1800 | 97.65 | 230-330 | 74-166 | 5.3x5.4x16.0 |

| VTM-2000 | 2000 | 109.47 | 258-370 | 83-185 | 5.5x5.6x16.4 |

Submit Request