[ Material ]: Lithium iron phosphate, battery recycling materials, coal-based kaolin, alkaline magnesium carbonate, magnesium hydroxide, magnesium chloride, molecular sieve catalyst, copper sulfate, barite, nickel oxide, titanium dioxide, zinc ore, sewage sediment, agricultural waste and industrial waste, etc.

[ Application fields ]: Materials such as non-metallic ore, metal ore, medicine, food, chemical products and agricultural products

Whatsapp:

+8613917653369Email:

[email protected]Our company has produced an electric heating rotary kiln that meets the actual needs of customers. This new type of practical environmental protection rotary kiln equipment has a compact structure. You can freely adjust the tilting angle and achieve precise control through temperature frequency adjustment. The heating elements adopt a modular design that is easy to replace. The equipment is easy to operate and convenient to maintain.

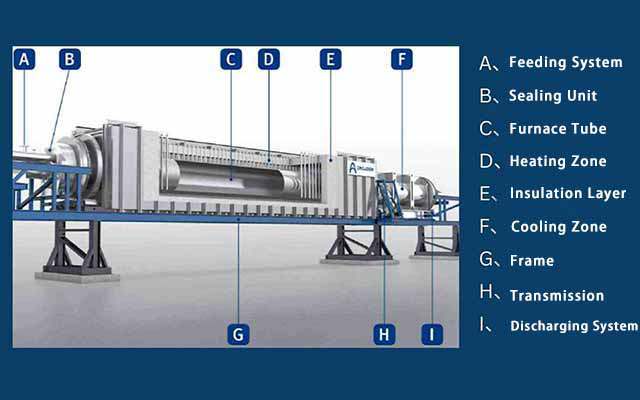

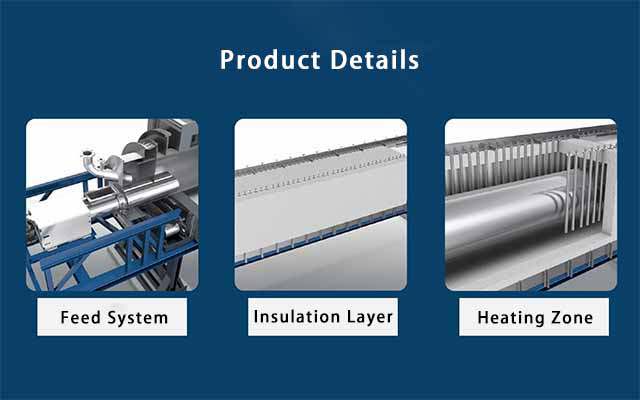

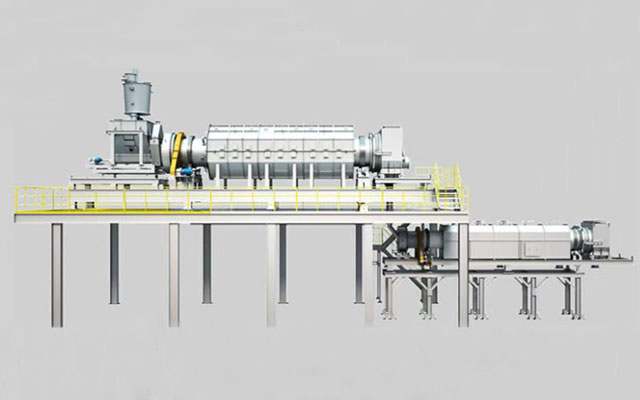

Product Components: The external heating electric rotary kiln is mainly composed of six parts: combustion system, control system, heating chamber cylinder, kiln body, drive unit, feeding and discharging system, etc.

The material is fed into the electric rotary kiln cylinder through a feeder, which distributes it evenly. The cylinder rotates with the help of a transmission device, and the material moves along the axial direction, while the coping plate rotates it to ensure even calcination. The cylinder is equipped with a heating chamber outside, which transfers the heat generated by calcination to the material through the cylinder. The material goes through a process of decomposition, drying, calcination, and roasting under high-temperature conditions. After the calcination process, the material is discharged through a discharge valve, cooled, and packaged for use.

| No. | Model | Operating temperature | Inner tube size | Heating power | Inclination | Productive capacity | Power supply | Weight |

| 1 | YDH100 | 1100℃ | φ0.1×4.5m | 36kW | 0.5~5.0° | ~4kg/h | 380VAC 50HZ | ~4T |

| 2 | YDH150 | 1100℃ | Φ0.15×4.5m | 42kW | 0.5~5.0° | ~8kg/h | 380VAC 50HZ | ~4T |

| 3 | YDH200 | 1100℃ | φ0.2×4.5m | 48kW | 0.5~5.0° | ~15kg/h | 380VAC 50HZ | ~4T |

| 4 | YDH350 | 1100℃ | φ0.35×9m | 68kW | 0.5~4.0° | ~120kg/h | 380VAC 50HZ | ~8T |

| 5 | YDH400 | 1100℃ | φ0.4×9m | 108kW | 0.5~4.0° | ~150kg/h | 380VAC 50HZ | ~10T |

| 6 | YDH500 | 1100℃ | φ0.5×9m | 180kW | 0.5~4.0° | ~250kg/h | 380VAC 50HZ | ~12T |

| 7 | YDH620 | 1100℃ | φ0.62×10.5m | 260kW | 0.5~3.0° | ~300kg/h | 380VAC 50HZ | ~15T |

| 8 | YDH700 | 1100℃ | φ0.7×10.5m | 280kW | 0.5~3.0° | ~360kg/h | 380VAC 50HZ | ~18T |

| 9 | YDH800 | 1100℃ | φ0.8×10.5m | 350kW | 0.5~3.0° | ~480kg/h | 380VAC 50HZ | ~20T |

| 10 | YDH940 | 1100℃ | φ0.94×12m | 400kW | 0.5~2.5° | ~650kg/h | 380VAC 50HZ | ~25T |

| 11 | YDH1000 | 1100℃ | φ1.0×12m | 410kW | 0.5~2.5° | ~750kg/h | 380VAC 50HZ | ~28T |

| 12 | YDH1100 | 1100℃ | φ1.1×12m | 460kW | 0.5~2.5° | ~900kg/h | 380VAC 50HZ | ~30T |

| 13 | YDH1250 | 1100℃ | φ1.25×12m | 500kW | 0.5~2.5° | ~1000kg/h | 380VAC 50HZ | ~35T |

| 14 | YDH1420 | 1100℃ | φ1.42×13.5m | 600kW | 0.5~2.5° | ~1350kg/h | 380VAC 50HZ | ~40T |

| 15 | YDH1500 | 1100℃ | φ1.5×13.5m | 750kW | 0.5~2.5° | ~1500kg/h | 380VAC 50HZ | ~45T |

| 16 | YDH1600 | 1100℃ | φ1.6×15m | 900kW | 0.5~2.5° | ~1600kg/h | 380VAC 50HZ | ~50T |

| 17 | YDH1800 | 1100℃ | φ1.8×15m | 1000kW | 0.5~2.5° | ~1900kg/h | 380VAC 50HZ | ~55T |

| 18 | YDH2000 | 1100℃ | φ2.0×15m | 1100kW | 0.5~2.5° | ~2200kg/h | 380VAC 50HZ | ~60T |

| 19 | YDH2200 | 1100℃ | Φ2.2×15m | 1300kW | 0.5~2.5° | ~2600kg/h | 380VAC 50HZ | ~70T |

Submit Request