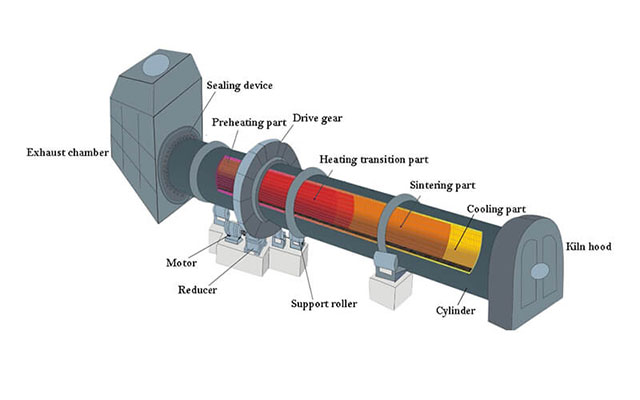

The pellet rotary kiln is a crucial equipment in metallurgical pelletizing projects. It is designed to solidify high-temperature pellet ores and is used in conjunction with a chain grate machine and a circular cooler to sinter high-temperature pellet ore into solid pellets.

Whatsapp:

+8613917653369Email:

[email protected]Our rotary kilns are manufactured using advanced technology and high-quality materials to ensure stable performance and durability. We provide customized solutions to meet your specific needs. No matter the size of the pelletized ore you need to process, we always have a solution for you. Please feel free to contact us to learn more about rotary kilns and how we can meet your pellet production needs.

The rotary kiln for pellets utilizes an inclined cylinder body and internal sprocket wheel device to achieve the solidification and roasting of high-temperature pellet ore. This is accomplished by repeatedly tumbling and advancing the pellets under the influence of hot air flow. The entire process takes approximately 25 to 35 minutes to complete.

| Specification (m) | Capacity (t/d) | Main Motor | Main reducer | Weight (t) | ||

| Model | Power(kw) | Model | Gear Ratio | |||

| φ1.8x26 | 72 | JZT2-72-4 | 30 | JZQ750-1-Ⅰ | 48.57 | 66 |

| φ2.2x45 | 98.4 | JZT82-6 | 55 | ZA125 | 93.93 | 104 |

| φ2.5x50 | 180 | ZT3-72-4 | 30 | ZS145-9-Ⅴ | 122.8 | 173 |

| φ3x48 | 700 | ZSN4-280-21 | 110 | MSY56-28-Ⅱ | 28 | 244 |

| φ3.2x50 | 1000 | ZSN4-280-21B | 160 | MSY56-28-Ⅱ | 28 | 252.4 |

| φ3.5x54 | 1500 | ZSN4-3156-092 | 220 | ZSY500-40-Ⅴ | 40 | 368 |

| φ3.9x56 | 2000 | Z4-280-32BTH | 250 | ZSY560-40-Ⅰ | 40 | 417 |

| φ4x60m | 2500 | ZSN4-355-09Z | 315 | ZSY630-35.5-Ⅰ | 34.6 | 523 |

| φ4.3x60m | 3000 | ZSN4-355-12 | 375 | ZSY710-40 | 40 | 553 |

| φ4.8x75m | 5000 | ZSN4-400-92 | 630 | JH710-40 | 42 | 841 |

Submit Request