The cement ball mill, also known as the cement mill, is the key grinding equipment used in the cement production process to grind finished products and raw materials. Its main function is to crush the materials and achieve the necessary fineness requirements.

Whatsapp:

+8613917653369Email:

[email protected]A cement mill is an important component of the cement manufacturing process in a cement plant. The cement ball mill is designed to grind materials in either a dry or wet mode, and it finds widespread usage across different production industries, including cement, silicate products, refractory materials, chemical fertilizers, ferrous and non-ferrous metal beneficiation, and glass ceramics.

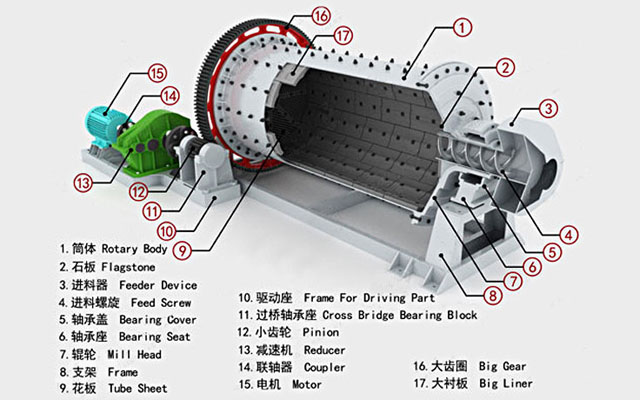

The parts of a cement mill include:

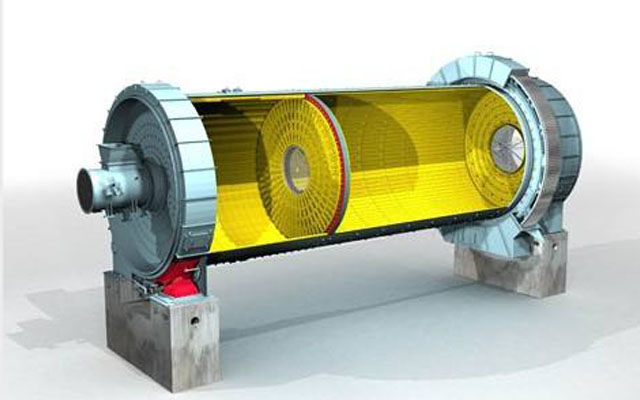

The material is fed uniformly into the first bin of the mill through the feeding device via the feeding hollow shaft spiral. Inside the bin is a ladder lining board or corrugated lining board, and steel balls of different sizes are installed. As the cylinder rotates, centrifugal force is generated, which lifts the steel balls to a certain height, and then they fall, creating a heavy impact and grinding effect on the material.

After the material is roughed in the first bin, it enters the second bin through the single-compartment board, which is inlaid with a flat lining board and contains steel balls to grind the material further. The powder is discharged through the unloading grates to complete the grinding operation. A cement mill has the characteristics of strong adaptability to materials, continuous production, large crushing ratio, and easy-to-adjust the fineness of grinding products. Cement mills can be produced by the wet method as well as by the wet method. It can also be ground and dried at the same time.

| Spec./m | Speed(r/min) | Feeding Size (mm) | Capacity(t/h) | Grinding Media Loading(t) | Main Motor (KW) | Main Reducer | Weight(t) |

| φ2.2×9.0 | 21.5 | <25 | 14~15 | 39 | 475 | ZD70 | 69 |

| φ2.2×9.5 | 21.5 | <25 | 14~16 | 41 | 475 | ZD70 | 74 |

| φ2.2×11 | 21.5 | <25 | 16~18 | 50 | 570 | ZD80 | 109 |

| φ2.2x13 | 21.5 | <25 | 20~22 | 58 | 630 | ZD80 | 114 |

| φ2.4x10 | 20.3 | <25 | 18~20 | 52 | 630 | ZD80 | 108 |

| φ2.4×11 | 20.3 | <25 | 19~22 (Open Circuit) | 57 | 630 | ZD80 | 116 |

| φ2.4×11 | 20.3 | <25 | 22~25(Circulating Load) | 57 | 630 | ZD80 | 116 |

| φ2.4×12 | 20.3 | <25 | 21~23(Open Circuit) | 63 | 800 | MBY710 | 128 |

| φ2.4×12 | 20.3 | <25 | 24~26(Circulating Load) | 63 | 800 | JDX710 | 128 |

| φ2.4×13 | 20.3 | <25 | 22~24(Open Circuit) | 68 | 800 | MBY710 | 138 |

| φ2.4×13 | 20.3 | <25 | 25~28(Circulating Load) | 68 | 800 | JDX710 | 138 |

| φ2.6×11 | 19.7 | <25 | 24~26 (Circulating Load) | 69 | 800 | MBY710 | 138 |

| JDX710 | |||||||

| φ2.6×13 | 19.7 | <25 | 28~32 | 82 | 1000 | MBY800 | 158 |

| φ2.6×13 | 19.7 | <25 | 28~32 | 82 | 1000 | JDX800 | 158 |

| φ3.0×9.0 | 18.2 | <25 | 28~32 | 78 | 1000 | MBY800 | 158 |

| φ3.0×9.0 | 18.2 | <25 | 28~32 | 78 | 1000 | JDX800 | 158 |

| φ3.0x11 | 18.2 | <25 | 31~35 | 95 | 1250 | MBY800 | 178 |

| φ3.0x11 | 18.2 | <25 | 31~35 | 95 | 1250 | JDX800 | 178 |

| φ3.0x12 | 18.2 | <25 | 32~36 | 100 | 1250 | MBY800 | 182 |

| φ3.0x12 | 18.2 | <25 | 32~36 | 100 | 1250 | JDX800 | 182 |

| φ3.0×13 | 18.2 | <25 | 33~37 | 108 | 1400 | MBY900 | 190 |

| φ3.0×13 | 18.2 | <25 | 33~37 | 108 | 1400 | JDX900 | 190 |

| φ3.2x11 | 17.8 | <25 | 40~45 | 110 | 1400 | MBY900 | 215 |

| φ3.2x11 | 17.8 | <25 | 40~45 | 110 | 1400 | JDX900 | 215 |

| φ3.2×13 | 17.8 | <25 | 45~50 | 128 | 1600 | MBY1000 | 230 |

| φ3.2×13 | 17.8 | <25 | 45~50 | 128 | 1600 | JDX1000 | 230 |

| φ3.2×13 | 17.7 | <25 | 50~55(Circulating Load) | 128 | 1600 | 1C120-A | 230 |

| φ3.2×13 | 17.7 | <25 | 50~55(Circulating Load) | 128 | 1600 | MFY160 | 230 |

| φ3.2×14 | 17.8 | <25 | 48~53 | 138 | 1800 | MBY1000 | 249 |

| φ3.2×14 | 17.8 | <25 | 48~53 | 138 | 1800 | JDX1000 | 249 |

| φ3.5x11 | 17.1 | <25 | 55~60(Circulating Load) | 135 | 1800 | JS120-B | 220 |

| φ3.5x11 | 17.1 | <25 | 55~60(Circulating Load) | 135 | 1800 | MFY180 | 220 |

| φ3.5×13 | 17.3 | <25 | 60~65(Circulating Load) | 156 | 2000 | JS130-A | 275 |

| φ3.8x12 | 17 | <25 | 63~68(Circulating Load) | 175 | 2500 | JS130-C | 197 |

| φ3.8x13 | 17 | <25 | 65~70(Circulating Load) | 190 | 2500 | JS130-C | 245 |

| φ4.0x13 | 16.3 | <25 | 75~80(Circulating Load) | 200 | 2800 | JS140-A | 250 |

| φ4.2x11 | 15.8 | <25 | 100~110(Circulating Load) | 195 | 2800 | JS140-A | 248 |

| φ4.2x13 | 15.8 | <25 | 110~120(Circulating Load) | 230 | 3150 | JS140-C | 255 |

| φ4.2×14 | 15.6 | <25 | 120~135(Circulating Load) | 252 | 3550 | JS150-B | 270 |

| φ4.2x15 | 15.6 | <25 | 140~150(Circulating Load) | 270 | 4000 | JS160-B | 288 |

| φ4.6×14 | 15.1 | <25 | 140~150(Circulating Load) | 285 | 4200 | JS160-C | 320 |

| φ4.6x15 | 15.1 | <25 | 150~160(Circulating Load) | 305 | 4500 | JS160-D | 335 |

Submit Request