The rod mill is a common grinding equipment that uses steel rods as grinding media. Shanghai YingYong manufactures the mill equipment, and features advanced controlled inlet and outlet technology. This technology combines the actual grinding material with the appropriate grinding body to achieve a more consistent particle size and a higher output.

Whatsapp:

+8613917653369Email:

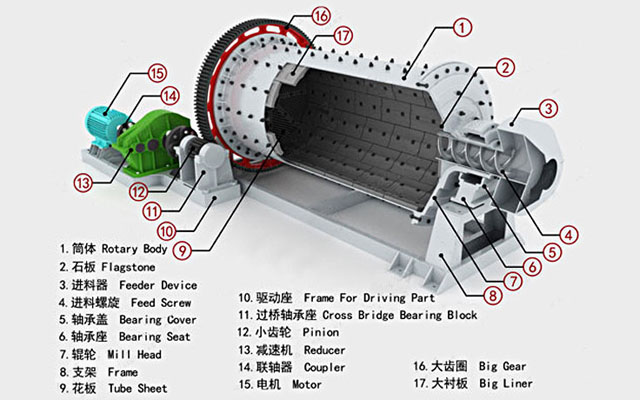

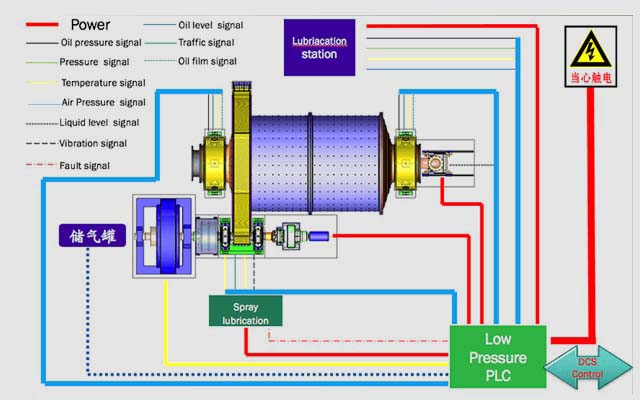

[email protected]Rod mills are generally of a wet overflow type and can be used as primary open circuit grinding. They are widely used in mineral processing plants, chemical plant power departments, and for grinding artificial stone sand. The mill consists of several parts, including a motor, main reducer, transmission department, cylinder department, main bearing, slow speed transmission department, feeding department, discharging department, ring seal, thin oil lubrication station, large and small gear jet lubrication, and foundation department.

The rod mill is an asynchronous motor connected with a small gear through a reducer, which directly drives the surrounding large gears to decelerate and rotate, and drives the rotary part to rotate. The cylinder is equipped with an appropriate grinding medium—steel rods. Under the action of the machine, the material to be ground continuously enters the inside of the cylinder from the feeding part, is crushed by the moving grinding medium, and the product is discharged out of the machine through the force of overflow and continuous feeding, so as to proceed to the next process deal with.

| Model | Volume(m³) | Cylinder Speed (r/min) | Max. bar capacity (t) | Motor(kw) | Weight (T) |

| Φ900×1800 | 0.9 | 35.4 | 2.5 | 22 | 5.37 |

| Φ900×2400 | 1.2 | 35.4 | 3.55 | 30 | 5.88 |

| Φ1500×3000 | 5 | 26 | 8 | 95 | 18 |

| Φ1500×3000 | 4.4 | 26 | 13 | 95 | 17.29 |

| Φ2100×3000 | 9 | 20.9 | 25 | 210 | 42.18 |

| Φ2100×3000 | 9 | 20.9 | 25 | 210 | 57 |

| Φ2700×3600 | 18.5 | 18 | 46 | 400 | 68 |

| Φ2700×4000 | 20.6 | 18 | 46 | 400 | 73.3 |

| Φ3200×4500 | 32.8 | 16 | 82 | 630 | 108 |

| Φ3600×4500 | 43 | 14.7 | 110 | 1000 | 159.9 |

| Φ3600×5400 | 50 | 15.1 | 124 | 1250 | 150 |

Submit Request