Common models of domestic reducers: NGC MLX, MLXSD, MLXSS series; heavy-toothed JLP, JLX, JLW series; imported Flender KMPS series; Hangzhou Auto HSG series (small market share).

Large-scale vertical mills are essential in the cement industry, and maintaining related components is crucial for normal production. Accidents can lead to difficult on-site maintenance, high technical demands, and long maintenance cycles, impacting operations. To address this, some cement enterprises purchase spare machines at a high cost, while others return entire machines to the factory for maintenance during production shutdowns, incurring significant transportation costs. This highlights the importance of on-site inspection and maintenance for large reducers.

Professional patrol inspection: The most important means to discover hidden troubles is equipment patrol inspection.

Common faults: high-speed shaft bearing damage, high-speed shaft bevel gear broken teeth, loose spacer sleeve between two bearings of high-speed shaft, wear on the surface of parallel shaft external tooth spline shaft and internal tooth spline sleeve, equipment vibration

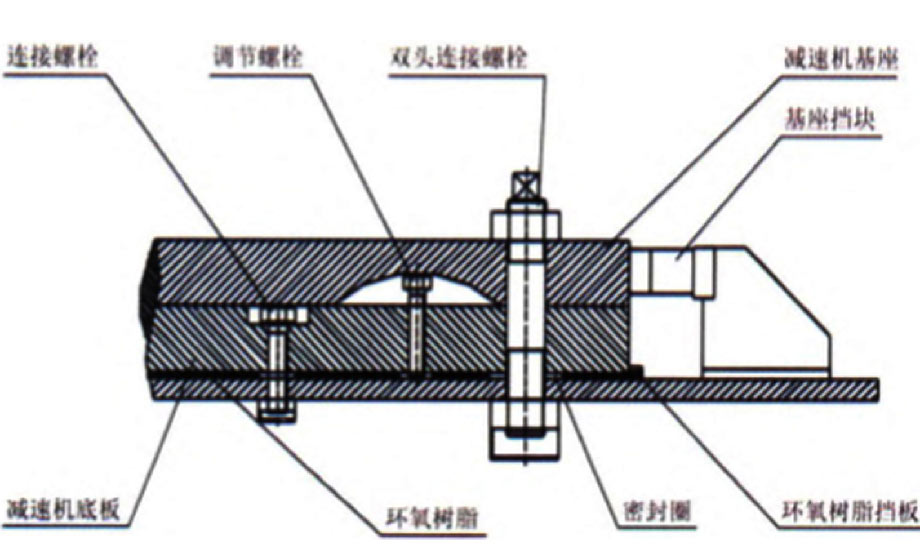

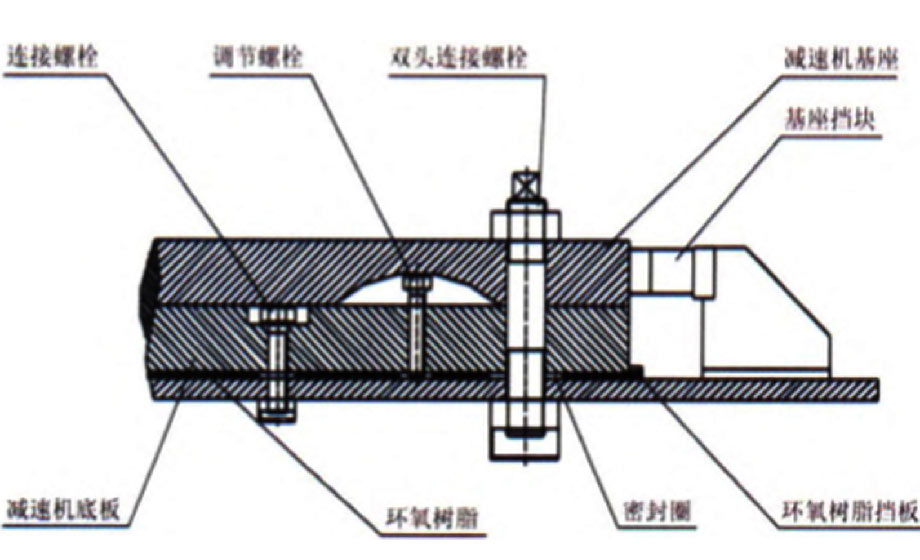

Troubleshooting: Invite a professional reducer maintenance team to enter the factory, selectively carry out on-site maintenance and return to the factory for maintenance, and deal with the shaking of the reducer foundation

Submit Request